process of manufacturing of sand and lime bricks

What is the best raw material ratio for fly ash bricks ...

Feb 12, 2018· Commonly, the raw materials of the fly ash bricks are cement, sand, crushed stone, fly ash, construction refuse, ceramisite and so on. As for the raw material ratio for fly ash bricks, I think the recipe in the following picture is very good. If you want to get more details about fly ash...

Feb 12, 2018· Commonly, the raw materials of the fly ash bricks are cement, sand, crushed stone, fly ash, construction refuse, ceramisite and so on. As for the raw material ratio for fly ash bricks, I think the recipe in the following picture is very good. If you want to get more details about fly ash...

Advantages Disadvantages of Bricks Civil Engineering

Bricks. Usually clays are composed mainly of silica (grains of sand), alumina, lime, iron, manganese, sulfur, and phosphates, with different proportions. Clay bricks have an average density of 125 pcf. Bricks are manufactured by grinding or crushing the clay in mills and mixing it with water to make it plastic.

Bricks. Usually clays are composed mainly of silica (grains of sand), alumina, lime, iron, manganese, sulfur, and phosphates, with different proportions. Clay bricks have an average density of 125 pcf. Bricks are manufactured by grinding or crushing the clay in mills and mixing it with water to make it plastic.

Researchers make bricks from waste, desert sand

By: Wagdy Sawahel. The bricks could be produced cheaply in the southern region of Algeria, where Saharan sand is especially plentiful and available at minimal cost, according to the study, which was published in December 2012 issue of the Arabian Journal for Science and Engineering. The researchers carried out 750 laboratory tests to hone the brick.

By: Wagdy Sawahel. The bricks could be produced cheaply in the southern region of Algeria, where Saharan sand is especially plentiful and available at minimal cost, according to the study, which was published in December 2012 issue of the Arabian Journal for Science and Engineering. The researchers carried out 750 laboratory tests to hone the brick.

Chapter 8 Flashcards | Quizlet

A brick or masonry unit laid in its most usual position, with the broadest surface of the unit horizontal and the length of the unit parallel to the surface of the wall. masonry unit A brick, stone, concrete block, glass block, or hollow clay tile intended to be laid in mortar.

A brick or masonry unit laid in its most usual position, with the broadest surface of the unit horizontal and the length of the unit parallel to the surface of the wall. masonry unit A brick, stone, concrete block, glass block, or hollow clay tile intended to be laid in mortar.

22 Lime Kiln Principles And Operations

bricks is lost and several complete rows of bricks fall out. Slide 11 shows two other features of the interior lining of rotary kilns that are used to improve heat transfer. The first feature is a set of lifters that are installed in the cold end of the kiln, usually just downhill from the chains. Lifters mix the lime mud and expose it to the hot

bricks is lost and several complete rows of bricks fall out. Slide 11 shows two other features of the interior lining of rotary kilns that are used to improve heat transfer. The first feature is a set of lifters that are installed in the cold end of the kiln, usually just downhill from the chains. Lifters mix the lime mud and expose it to the hot

Classification of Bricks | Types of Bricks.

The principal raw materials for sandlime bricks are: (1) Sand. It must be free from harmful impurities like chloride, iron oxides, black minerals and organic matter. Sand forms around 90 percent of sandlime bricks. (ii) Lime. It is used in the form of a slaked (hydrated) lime. Its content varies from 812 percent.

The principal raw materials for sandlime bricks are: (1) Sand. It must be free from harmful impurities like chloride, iron oxides, black minerals and organic matter. Sand forms around 90 percent of sandlime bricks. (ii) Lime. It is used in the form of a slaked (hydrated) lime. Its content varies from 812 percent.

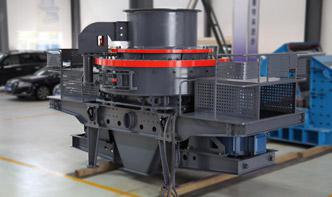

sand brick manufacturing machines supplys

Many brick have smooth or sand ... » More; Production of Sand Lime Brick and Fitting Pieces . Purpose Built Using Proven Technology. ... define the machine designs and capacities as well as the process sequence ... sand lime brick product requires ultimate ... » More; Brick Making Machines Brick .

Many brick have smooth or sand ... » More; Production of Sand Lime Brick and Fitting Pieces . Purpose Built Using Proven Technology. ... define the machine designs and capacities as well as the process sequence ... sand lime brick product requires ultimate ... » More; Brick Making Machines Brick .

New CO2 Sand Bricks are Times Stronger than Concrete

New CO2 Sand Bricks are Times Stronger than Concrete. The process of making the brick uses carbon dioxide to harden sand and a binder to provide tensile strength. In fact, the inventor claims the bricks are times the tensile strength of concrete in one day, meaning that the construction of walls would need much less steel reinforcement and could be used immediately in emergency constructions.

New CO2 Sand Bricks are Times Stronger than Concrete. The process of making the brick uses carbon dioxide to harden sand and a binder to provide tensile strength. In fact, the inventor claims the bricks are times the tensile strength of concrete in one day, meaning that the construction of walls would need much less steel reinforcement and could be used immediately in emergency constructions.

Field Tests on Soil to Determine Suitability of Soil for ...

Apr 21, 2014· LIME TEST. Lime is one of the most dangerous mineral for brick making. The presence of lime in soil defines whether to start a brick business or not if no other alternative soil is available. The presence of lime needs to be detected during the initial soil testing stage only. It .

Apr 21, 2014· LIME TEST. Lime is one of the most dangerous mineral for brick making. The presence of lime in soil defines whether to start a brick business or not if no other alternative soil is available. The presence of lime needs to be detected during the initial soil testing stage only. It .

Compressive Strength of Fly Ash Brick with Addition of ...

After processing fine particles of size less than mm is used in this work. First Arriving mix percentage of flyash bricks for Flyash (15 to 50%), Lime (5 to 30%), Gypsum (2%) and Quarry dust (45 to 55%).Standard flyash brick size of 230 mm x 110mm x 90 mm are used to cast the bricks.

After processing fine particles of size less than mm is used in this work. First Arriving mix percentage of flyash bricks for Flyash (15 to 50%), Lime (5 to 30%), Gypsum (2%) and Quarry dust (45 to 55%).Standard flyash brick size of 230 mm x 110mm x 90 mm are used to cast the bricks.

How To Calculate Number Of Bricks, Cement And Sand For ...

How To Calculate Number Of Bricks, Cement And Sand For Brickwork? – With Calculator Most of the structural buildings comprise 75% of brickwork (at least in Asian countries).

How To Calculate Number Of Bricks, Cement And Sand For Brickwork? – With Calculator Most of the structural buildings comprise 75% of brickwork (at least in Asian countries).

Which type of lime is used in the manufacturing of cement ...

The type of lime used with cement and sand for laying bricks mortar is called "quicklime" which is a different material altogether. Lime, or quicklime, improves workability but has negligible effect on strength of mortar To make Portland cement, limestone is crushed to a .

The type of lime used with cement and sand for laying bricks mortar is called "quicklime" which is a different material altogether. Lime, or quicklime, improves workability but has negligible effect on strength of mortar To make Portland cement, limestone is crushed to a .

Defects in brick masonry SlideShare

Jul 19, 2016· Defects in brick masonry. 2. DEFECTS DURING MANUFACTURING PROCESS DEFECTS IN SIZE Oversize in all 3 dimensions • The brick may be underfired. • The presence of too much sand will decrease the amount of drying. • The brick will be lighter than normal, and there will be a dull "ring "when knocked with another brick instead of a metallic sound.

Jul 19, 2016· Defects in brick masonry. 2. DEFECTS DURING MANUFACTURING PROCESS DEFECTS IN SIZE Oversize in all 3 dimensions • The brick may be underfired. • The presence of too much sand will decrease the amount of drying. • The brick will be lighter than normal, and there will be a dull "ring "when knocked with another brick instead of a metallic sound.

Burntclay bricks

The manufacturing process aims to produce a material with a high content of tricalcium silicate, usually 55 to 62% of the crystals in the clinker. Other crystals formed are: about 15% dicalcium silicate, (the same component as the hydraulic binder in hydraulic lime), 8 to 10% tricalcium aluminate and 9% tetracalcium aluminate ferrite.

The manufacturing process aims to produce a material with a high content of tricalcium silicate, usually 55 to 62% of the crystals in the clinker. Other crystals formed are: about 15% dicalcium silicate, (the same component as the hydraulic binder in hydraulic lime), 8 to 10% tricalcium aluminate and 9% tetracalcium aluminate ferrite.

Bricks | Brick | Lime (Material)

(Walls, foundation, column, retaining walls) Bricks are made chiefly from nonorganic materials Main materials: clay sand lime cement INTRODUCTION Methods of manufacturing bricks: Handmade Pressed Wirecut Standard size 215mm (length) x (width) x 65mm (thickness) Wellmade bricks are hard and durable.

(Walls, foundation, column, retaining walls) Bricks are made chiefly from nonorganic materials Main materials: clay sand lime cement INTRODUCTION Methods of manufacturing bricks: Handmade Pressed Wirecut Standard size 215mm (length) x (width) x 65mm (thickness) Wellmade bricks are hard and durable.

Manufacturing of Stabilized Soil Bricks IOSR Journals

The idea "use of foundry sand in bricks" was generated from there because foundry sand is high silica sand and the due to presence of high silica content the strength is also good enough. II. Material used 1. OPC: The ordinary Portland cement of grade 43, used in this brick for binding and strength purposes. 2.

The idea "use of foundry sand in bricks" was generated from there because foundry sand is high silica sand and the due to presence of high silica content the strength is also good enough. II. Material used 1. OPC: The ordinary Portland cement of grade 43, used in this brick for binding and strength purposes. 2.

الوظائف ذات الصلة

- إصلاح الخرسانة حول كسارة الفحم

- مقال عن آلة طاحونة

- تصميم آلة مطحنة المطرقة بالتفصيل

- الثانوية محطم بحجم

- خام الحديد التعدين على نطاق صغير من الجزائر

- الحجر المحمول المعدات محطم في مصر قوات الدفاع الشعبي

- آلة غسل الرمال المتنقلة لبيع

- المعدات اللازمة لتعدين البوكسيت

- جنوب الإمارات العربية المتحدة خام الحديد كسارة

- والمحمول الفك محطم

- biodiversecity st louis missouri botanical garden

- jaw crusher manufacturer or supplier

- international harvestor hammer mills

- screw conveyor calculation exel free

- batch plants new concrete batch plants used cement plants

- sand screw installation

- working princple of crusher

- machine milling boring

- rock jaw crushers for sale

- cement industry bosch rexroth ag

معلومات عنا

واستنادا إلى استراتيجية "خدمة الترجمة"، وضعت كروشر 22 مكتبا في الخارج. إذا كان لديك أي أسئلة، يمكنك إجراء اتصالات مع مكتب قريب مباشرة. سوف كروشر نقدم لكم حلول لمشاكلك بسرعة.

Ccrusher

WhatsApp

WhatsApp