cement plant vertical raw mill german made

compare raw mill with cement mill

cement plant vertical raw mill german made Very good loesche raw mill cement mill in al ain cement company in UAE .... LOESCHE is involved in the new construction of a large cement plant in Egypt with three vertical roller mills.

cement plant vertical raw mill german made Very good loesche raw mill cement mill in al ain cement company in UAE .... LOESCHE is involved in the new construction of a large cement plant in Egypt with three vertical roller mills.

Manufacturing – BGC Cement

BGC Cement offers a large range of packaged cements, cement and lime blends, hydrated lime and drymix products under its BUILDERS CHOICE brand name. Bagged using a stateoftheart German engineered and manufactured Haver rotopacker filling machine, we bag over 6,000 sacks per day.

BGC Cement offers a large range of packaged cements, cement and lime blends, hydrated lime and drymix products under its BUILDERS CHOICE brand name. Bagged using a stateoftheart German engineered and manufactured Haver rotopacker filling machine, we bag over 6,000 sacks per day.

Manufacture of Portland cement

Portland Cement . Cement: is a material with adhesive and cohesive properties which make it capable of bonding minerals fragments into a compact whole. For constructional purposes, the meaning of the term "cement" is restricted to the bonding materials used with stones, sand, bricks, building stones, etc.

Portland Cement . Cement: is a material with adhesive and cohesive properties which make it capable of bonding minerals fragments into a compact whole. For constructional purposes, the meaning of the term "cement" is restricted to the bonding materials used with stones, sand, bricks, building stones, etc.

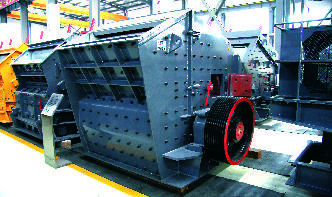

raw mill of cement plant complete detail with images

Cement manufacturing components of a cement plant Cement manufacturing process components of a cement plant from quarry to ... of the individual components of a cement plant the kiln, the cement mill etc. ... For a more detailed account of the cement production process, see the ... These raw materials are extracted from the quarry crushed to a very fine ...

Cement manufacturing components of a cement plant Cement manufacturing process components of a cement plant from quarry to ... of the individual components of a cement plant the kiln, the cement mill etc. ... For a more detailed account of the cement production process, see the ... These raw materials are extracted from the quarry crushed to a very fine ...

relocating vertical raw mill in cement industry BINQ Mining

Nov 12, 2012· LM Series Vertical Mill Our crusher Heavy Industry (Shanghai). Vertical Mill Introduction: Vertical mill is a type of milling equipment widely used in cement, chemical industry, . the raw material is transferred into the raw . »More detailed

Nov 12, 2012· LM Series Vertical Mill Our crusher Heavy Industry (Shanghai). Vertical Mill Introduction: Vertical mill is a type of milling equipment widely used in cement, chemical industry, . the raw material is transferred into the raw . »More detailed

LOESCHE is involved in the extension of the largest cement ...

LOESCHE's order for the new production line 5 in Obajana comprises a high performance 6roller mill for cement raw meal with a capacity of 580 t/h – the largest roller mill for raw material in ...

LOESCHE's order for the new production line 5 in Obajana comprises a high performance 6roller mill for cement raw meal with a capacity of 580 t/h – the largest roller mill for raw material in ...

working of vertical raw mill in cement plant

working vertical roller cement mill in cement plant. Vertical roller mill for raw Application p rocess materials. Schematic process flow of vertical roller mill for grinding of raw materials Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan.

working vertical roller cement mill in cement plant. Vertical roller mill for raw Application p rocess materials. Schematic process flow of vertical roller mill for grinding of raw materials Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan.

WORLD CEMENT

their Viacha cement plant, located 22 km outside the capital city of La Paz, Bolivia. The scope of the supply contract includes cement grinding system equipment, engineering, and site advisory services. This will be the first vertical roller mill for cement grinding in Bolivia, and will produce high strength cement with 5000 Blaine.

their Viacha cement plant, located 22 km outside the capital city of La Paz, Bolivia. The scope of the supply contract includes cement grinding system equipment, engineering, and site advisory services. This will be the first vertical roller mill for cement grinding in Bolivia, and will produce high strength cement with 5000 Blaine.

Our vertical roller mill offers optimum raw, cement and ...

Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency. It is affordable to install and cost effective to operate over your cement plant.

Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency. It is affordable to install and cost effective to operate over your cement plant.

Process Operator Training for the cement industry VDZ

Process Operator Training Operators are responsible for keeping equipment running a high level of availability, optimising production rates and reducing energy consumption. This training will enable participants to have a better understanding of the process and how to optimise quality and reduce electrical energy as well as fuel consumption.

Process Operator Training Operators are responsible for keeping equipment running a high level of availability, optimising production rates and reducing energy consumption. This training will enable participants to have a better understanding of the process and how to optimise quality and reduce electrical energy as well as fuel consumption.

Tube mill/Ball mill/Cement mill/Coal mill/Slag mill/Raw ...

Tube mill/Ball mill/Cement mill/Coal mill/Sl... vertical mill/roller press/grinding equipment Product of Crusher Series Dust collector/environment equipment Equipment for power plantdesulfidation ball... Cooling Equipment/cooling machinery Drying Equipment Conveying .

Tube mill/Ball mill/Cement mill/Coal mill/Sl... vertical mill/roller press/grinding equipment Product of Crusher Series Dust collector/environment equipment Equipment for power plantdesulfidation ball... Cooling Equipment/cooling machinery Drying Equipment Conveying .

cement plant horizontal raw mill sealing

Ball mill / horizontal / for cement / large FCB BMill ... The ball mill is traditionally the basic system used for the grinding of raw material, clinker and additives in a cement plant.

Ball mill / horizontal / for cement / large FCB BMill ... The ball mill is traditionally the basic system used for the grinding of raw material, clinker and additives in a cement plant.

grinding mill for sale

Grinding Mill Manufacturer is a professional grinding mill manufacturer in Shanghai, China. Our stone crushers and grinding mill unit [...] Grinding Mill Manufacturer is a professional grinding mill manufacturer in Shanghai, China. Our stone... Iron Ore Beneficiation Process Plant

Grinding Mill Manufacturer is a professional grinding mill manufacturer in Shanghai, China. Our stone crushers and grinding mill unit [...] Grinding Mill Manufacturer is a professional grinding mill manufacturer in Shanghai, China. Our stone... Iron Ore Beneficiation Process Plant

Coplay Cement Company Kilns National Register of ...

Several years before he constructed his first cement plant in 1866, Saylor purchased the land where it and the future mills of the Coplay Cement Company would be located. His first mill, often referred to as plant A, where he made his first portland cement in 1871, was utilized well into the 1890s but was demolished early in the 20th century.

Several years before he constructed his first cement plant in 1866, Saylor purchased the land where it and the future mills of the Coplay Cement Company would be located. His first mill, often referred to as plant A, where he made his first portland cement in 1871, was utilized well into the 1890s but was demolished early in the 20th century.

Cement manufacturing components of a cement plant

Cement is typically made from limestone and clay or shale. These raw materials are extracted from the quarry crushed to a very fine powder and then blended in the correct proportions. This blended raw material is called the 'raw feed' or 'kiln feed' and is heated in a rotary kiln where it reaches a temperature of about 1400 C to 1500 C.

Cement is typically made from limestone and clay or shale. These raw materials are extracted from the quarry crushed to a very fine powder and then blended in the correct proportions. This blended raw material is called the 'raw feed' or 'kiln feed' and is heated in a rotary kiln where it reaches a temperature of about 1400 C to 1500 C.

ENERGY AUDIT OF THERMAL UTILITIES IN A CEMENT PLANT

ENERGY AUDIT OF THERMAL UTILITIES IN A CEMENT PLANT ... German Cement Industry. The research was based on electrical and thermal energy saving methods. ... The plant has one raw mill of capacity ...

ENERGY AUDIT OF THERMAL UTILITIES IN A CEMENT PLANT ... German Cement Industry. The research was based on electrical and thermal energy saving methods. ... The plant has one raw mill of capacity ...

vibration vertical roller mill International Cement Review

Mar 01, 2016· re vibration vertical roller mill. There are a number of reasons for high vibrations in vertical roller mills, such as: 1. Failure of the grout or cement material under the steel beams embedded in the foundation top, which allows oil to penetrate, further degrading the concrete.

Mar 01, 2016· re vibration vertical roller mill. There are a number of reasons for high vibrations in vertical roller mills, such as: 1. Failure of the grout or cement material under the steel beams embedded in the foundation top, which allows oil to penetrate, further degrading the concrete.

Process Of Vertical Raw Mill In Cement Plant Pdf

Raw mill for cement plant design. Raw mill in cement plant pdf zacarafarm raw mill in cement plant pdf manveesingh pulverizer wikipedia a pulverizer or grinder is a mechanical device for the grinding of many different types of materials for example a pulverizer mill is used to . remove; Cement .

Raw mill for cement plant design. Raw mill in cement plant pdf zacarafarm raw mill in cement plant pdf manveesingh pulverizer wikipedia a pulverizer or grinder is a mechanical device for the grinding of many different types of materials for example a pulverizer mill is used to . remove; Cement .

Concrete Batching Plant |Germany vertical mill for raw ...

Germany vertical mill for raw material milling for cement plant The process flow for stationary concrete batch plant will start from feeding of aggregates to the feeder bins. Process of concrete mixing plants end at the output of fresh concrete from the mixer.

Germany vertical mill for raw material milling for cement plant The process flow for stationary concrete batch plant will start from feeding of aggregates to the feeder bins. Process of concrete mixing plants end at the output of fresh concrete from the mixer.

GrafGalenStraße 17 industry

operation in a cement plant in Halimoru, Turkey, since 2017. 180° In the polysius ® automated storage sys tem a 180° slewing belt stacker installed in the middle runs up and down on rails. Raw material preparation From the quarry to preheater feeding with raw meal The cement manufacturing process starts with the extraction

operation in a cement plant in Halimoru, Turkey, since 2017. 180° In the polysius ® automated storage sys tem a 180° slewing belt stacker installed in the middle runs up and down on rails. Raw material preparation From the quarry to preheater feeding with raw meal The cement manufacturing process starts with the extraction

FCB Horomill® Fives in Cement | Minerals

Customer benefits. The lowest energy consumption: from 30% to 65% compared to ball mill, from 10% to 20% compared to vertical mill. The best product quality with lower clinker ratio. Zero water consumption. No need of grinding aid for blended cements or slags. Higher cement quality with lower Blaine.

Customer benefits. The lowest energy consumption: from 30% to 65% compared to ball mill, from 10% to 20% compared to vertical mill. The best product quality with lower clinker ratio. Zero water consumption. No need of grinding aid for blended cements or slags. Higher cement quality with lower Blaine.

Tube Mills KHD International

KHD Humboldt Wedag mills are spacesaving, compact, high on performance and low on maintenance. This is primarily due to the support bearing design and the mill drive used. The mill is shellsupported, mounted on slide shoe bearings at both ends and made completely as a welded design.

KHD Humboldt Wedag mills are spacesaving, compact, high on performance and low on maintenance. This is primarily due to the support bearing design and the mill drive used. The mill is shellsupported, mounted on slide shoe bearings at both ends and made completely as a welded design.

Grinding Mills | Ultrafine Grinding Mill

Raw Mill Raw mill is mainly used in grinding raw materials and end products in cement plant. It is also suitable in metallurgy, mine, chemical engineering and construction industries.

Raw Mill Raw mill is mainly used in grinding raw materials and end products in cement plant. It is also suitable in metallurgy, mine, chemical engineering and construction industries.

الوظائف ذات الصلة

- كيف الكسارات الفك تعمل

- تصميم الدولوميت مصنع طحن

- الحسابات تصميم دوارة مجفف

- الصخور سحق وغربلة النباتات مقطورة شنت المملكة العربية السعودية

- يجعل كسارة أوامر التجمع حجر

- ماكينات مصانع الاسمنت المصغرة فى مصر

- مصنعي كسارة الحجر من العراق

- كيفية رسم الرسم البياني للكسارة الفكية

- طرق الحجر الجيري التعدين

- كسارة الكلي للبيع في أفريقيا

- copper mining equipment used in the 20th century

- price sand washing station

- perhitungan dukungan semi layar getaran

- dead space 1 registro de antecedentes historicos

- mining industry equipment color coding

- impact crusher gold recovery

- mine waste rock sorting stainless steel

- line diagram of the manufacture of cement by wet process

- batu pengumpan getaran

- europe makes jaw crusher

معلومات عنا

واستنادا إلى استراتيجية "خدمة الترجمة"، وضعت كروشر 22 مكتبا في الخارج. إذا كان لديك أي أسئلة، يمكنك إجراء اتصالات مع مكتب قريب مباشرة. سوف كروشر نقدم لكم حلول لمشاكلك بسرعة.

Ccrusher

WhatsApp

WhatsApp