milling and spray drying

Spray Encapsulation of Pharmaceutical Products

Spray Drying Spray drying is suitable for producing heatsensitive products, with particle size ranging from 1 to 250 micrometers. Spray drying enables small average particle size with a narrow range of particle size distribution. Characteristics of spray drying .

Spray Drying Spray drying is suitable for producing heatsensitive products, with particle size ranging from 1 to 250 micrometers. Spray drying enables small average particle size with a narrow range of particle size distribution. Characteristics of spray drying .

Design of selfdispersible dry ... ScienceDirect

Nov 20, 2013· The spray freezedrying (SFD) technique was applied as a drying process instead of the spray drying (SD) one in the same manner as reported before (Kondo et al., 2009). A whole vessel of suspension obtained through the above milling process was passed through a sieve with 150 μmopening to remove the beads from the suspension.

Nov 20, 2013· The spray freezedrying (SFD) technique was applied as a drying process instead of the spray drying (SD) one in the same manner as reported before (Kondo et al., 2009). A whole vessel of suspension obtained through the above milling process was passed through a sieve with 150 μmopening to remove the beads from the suspension.

Three highly researched 3D metal powder ...

Spray Drying. Spray drying is a method of producing a dry 3D metal powder from a liquid or slurry by rapidly drying it with a hot gas. This method is used for producing Nanoscale particles. A total of 10 patents is filed for the process of manufacturing metal powder for additive manufacturing using spray drying since 2015.

Spray Drying. Spray drying is a method of producing a dry 3D metal powder from a liquid or slurry by rapidly drying it with a hot gas. This method is used for producing Nanoscale particles. A total of 10 patents is filed for the process of manufacturing metal powder for additive manufacturing using spray drying since 2015.

EVALUATION AND CHARACTERISATION OF .

process of ball milling and spray drying. Following questions have been made: How do the particles look like? Can we preserve the nanostructure after spray drying? Are there any changes in their chemical or physical properties? What about their crystallinity? Do we need excipients to keep a reasonable dissolution rate after spray drying?

process of ball milling and spray drying. Following questions have been made: How do the particles look like? Can we preserve the nanostructure after spray drying? Are there any changes in their chemical or physical properties? What about their crystallinity? Do we need excipients to keep a reasonable dissolution rate after spray drying?

Equipment List Spray Drying Valparaiso, Indiana

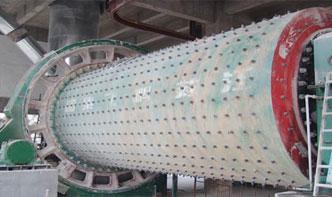

Steel Ball Mill (3' x 3') with Hardened CSteel grinding media; Ceramic Ball Mill (1,000 liter) with high Alumina grinding media; Dry Mills Hammer Mill; Prater Mill; Sweco Vibratory Mill; Spray Drying Equipment. Bowen Nozzle Tower™ Dryer; 9'6" Anhydro Spray Dryer Nozzle Dryer 80 150 microns Dv50; Complement Equipment. Blue M Ovens

Steel Ball Mill (3' x 3') with Hardened CSteel grinding media; Ceramic Ball Mill (1,000 liter) with high Alumina grinding media; Dry Mills Hammer Mill; Prater Mill; Sweco Vibratory Mill; Spray Drying Equipment. Bowen Nozzle Tower™ Dryer; 9'6" Anhydro Spray Dryer Nozzle Dryer 80 150 microns Dv50; Complement Equipment. Blue M Ovens

Home Spray Nozzle Engineering

Spray Nozzle Engineering is an international manufacturer and distributor of unique patented spray nozzles, paper mill nozzles, fire protection nozzles, spray dry nozzles and check valves. Find out more

Spray Nozzle Engineering is an international manufacturer and distributor of unique patented spray nozzles, paper mill nozzles, fire protection nozzles, spray dry nozzles and check valves. Find out more

Formulation strategy and use of excipients in pulmonary ...

These techniques are distinctly different from milling in that the particles are built up (, particle size is increased) whereas particle size is decreased during milling. Spray drying. Spray drying is a onestep process that converts a liquid feed to a dried particulate.

These techniques are distinctly different from milling in that the particles are built up (, particle size is increased) whereas particle size is decreased during milling. Spray drying. Spray drying is a onestep process that converts a liquid feed to a dried particulate.

Spray Drying ThomasNet

Custom powder processing including spray drying services for ceramic and inorganic materials. All types of spray dryers are used to handle any size of toll powder processing requirements. Material powders such as advanced ceramic, ferrite, mineral, zeolite, alumina, clay, mixed metal oxide and ...

Custom powder processing including spray drying services for ceramic and inorganic materials. All types of spray dryers are used to handle any size of toll powder processing requirements. Material powders such as advanced ceramic, ferrite, mineral, zeolite, alumina, clay, mixed metal oxide and ...

Is Spray Drying a Viable Alternative to Lyophilization ...

Dec 16, 2009· Spray drying is an alternative technique for preserving biopharmaceuticals, but it is relatively new to the industry. Equipment and Processing Report (EPR) talked to Satoshi Ohtake, research and development scientist at Aridis Pharmaceuticals (San Jose, CA), to find out when spray drying might be a reasonable alternative to lyophilization.

Dec 16, 2009· Spray drying is an alternative technique for preserving biopharmaceuticals, but it is relatively new to the industry. Equipment and Processing Report (EPR) talked to Satoshi Ohtake, research and development scientist at Aridis Pharmaceuticals (San Jose, CA), to find out when spray drying might be a reasonable alternative to lyophilization.

industrial milling and spray drying machine

BETE Spray Dry Manual. In the world of industrial dryers, there are few types that accept pumpable fluids as the feed material at the inlet end of the process and produce dry The development of spray drying equipment and techniques evolved over a period of several .

BETE Spray Dry Manual. In the world of industrial dryers, there are few types that accept pumpable fluids as the feed material at the inlet end of the process and produce dry The development of spray drying equipment and techniques evolved over a period of several .

Optimizing Particle Engineering Methods for Inhalation ...

Jet milling and spray drying are two particle engineering methods used to optimize particle properties. Pharmaceutical Technology spoke with Herbert Chiou, PhD, product development lead (inhalation novel therapeutics), and Salvatore Mercuri, RD Manager, both at Lonza Pharma Biotech, about optimizing and scaling up micronization processes. ...

Jet milling and spray drying are two particle engineering methods used to optimize particle properties. Pharmaceutical Technology spoke with Herbert Chiou, PhD, product development lead (inhalation novel therapeutics), and Salvatore Mercuri, RD Manager, both at Lonza Pharma Biotech, about optimizing and scaling up micronization processes. ...

Wet Corn Milling Energy Guide

Corn wet milling is the most energy intensive industry within the food and kindred products group (SIC 20), using 15% of the energy in the entire food industry . After corn, energ y is the second largest operating cost for corn wet millers in the United States. A typical corn wet milling .

Corn wet milling is the most energy intensive industry within the food and kindred products group (SIC 20), using 15% of the energy in the entire food industry . After corn, energ y is the second largest operating cost for corn wet millers in the United States. A typical corn wet milling .

Enhancing Dissolution of Poorly Soluble Drugs through Jet ...

Citation: When referring to this article, please cite it as P. Iamartino and S. Mercuri, "Enhancing Dissolution of Poorly Soluble Drugs through JetMilling," Pharmaceutical Technology 39 (2) 2015.

Citation: When referring to this article, please cite it as P. Iamartino and S. Mercuri, "Enhancing Dissolution of Poorly Soluble Drugs through JetMilling," Pharmaceutical Technology 39 (2) 2015.

Drying Henry Broch Foods

Air Drying. Air drying is a food preservation method in which the water in ingredients is removed through evaporation by bringing materials being dried into direct contact with cold or hot air. Air drying deters the growth of bacteria, yeast and mold and has been used for centuries. Why Air Dry?

Air Drying. Air drying is a food preservation method in which the water in ingredients is removed through evaporation by bringing materials being dried into direct contact with cold or hot air. Air drying deters the growth of bacteria, yeast and mold and has been used for centuries. Why Air Dry?

WOA3 Thermally stable aluminum trihydroxide ...

Thermally stable aluminum trihydroxide particles produced by spray drying with subsequent drymilling and their use JPA JPA (en) : : Using thermostable aluminum trihydroxide particles produced and these in dry grinding followed by spraydrying

Thermally stable aluminum trihydroxide particles produced by spray drying with subsequent drymilling and their use JPA JPA (en) : : Using thermostable aluminum trihydroxide particles produced and these in dry grinding followed by spraydrying

Toll Milling ThomasNet

Custom toll milling services for materials such as food products, ceramics, and pigments. Offers bead, ball, cryo, hammer, and jet milling and jaw crushing services. Capable of processing particles into submicron and nanometer size ranges. Provides processing .

Custom toll milling services for materials such as food products, ceramics, and pigments. Offers bead, ball, cryo, hammer, and jet milling and jaw crushing services. Capable of processing particles into submicron and nanometer size ranges. Provides processing .

Processing of Syndiotactic Polystyrene to Microspheres for ...

Syndiotactic polystyrene pellets were processed into powder form using mechanical (ball milling, rotor milling) and physicochemical (spray drying) techniques with the intention of using it as feed material for selective laser sintering. New materials are an important component in broadening the application window for selective laser sintering but must meet strict requirements to be used.

Syndiotactic polystyrene pellets were processed into powder form using mechanical (ball milling, rotor milling) and physicochemical (spray drying) techniques with the intention of using it as feed material for selective laser sintering. New materials are an important component in broadening the application window for selective laser sintering but must meet strict requirements to be used.

Dairy | Relco Pacific

Dairy. RELCO Pacific equipment and total systems for the processing of dairy products including milk reception, dry and liquid blending, evaporation, drying, CIPable bag filters, powder conveying and bulk and consumer packaging lines.

Dairy. RELCO Pacific equipment and total systems for the processing of dairy products including milk reception, dry and liquid blending, evaporation, drying, CIPable bag filters, powder conveying and bulk and consumer packaging lines.

الوظائف ذات الصلة

- كفاءة مطحنة الكرة المطحنة وكسارة الفك

- طاحونة معدات درفلة من أوكرانيا

- آلة مطحنة للمطعم الصناعي

- سحق اليدوي من الجرانيت في المحجر الأعمال مصر

- مصنع غسيل الذهب على نطاق واسع

- الاستخدامات الصناعية لكسارة القرص

- تأثير خصائص الفحم الجزائري

- الفرق بين الفحم المستورد والفحم المحلي

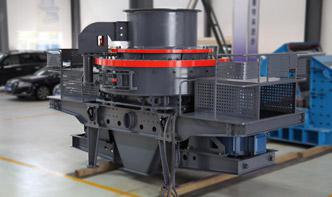

- كسارة مركب عمودي كسارة للحجارة الصلبة

- عملية تكسير وغربلة مصانع الذهب

- الطلب في السوق لسحق الخرسانة

- used coal crusher manufacturer in angola

- mobile jaw crusher in argentina

- is there a quarry in congo

- talc powder agriculture ground

- short head cone crusher model query

- barite mining process diagram

- mini plant project report white cement

- grinding ball mill manufacturer

- p amp h mining equipment linked nov

معلومات عنا

واستنادا إلى استراتيجية "خدمة الترجمة"، وضعت كروشر 22 مكتبا في الخارج. إذا كان لديك أي أسئلة، يمكنك إجراء اتصالات مع مكتب قريب مباشرة. سوف كروشر نقدم لكم حلول لمشاكلك بسرعة.

Ccrusher

WhatsApp

WhatsApp