vertical bowl mill ppt

COAL MILLS FOR THERMAL STATIONS

Dec 13, 2011· A vertical spindle mill is also designed for pressurized and suction type requirements. Boiler designers use this type of mill for poor quality coal as this type of mill rejects foreign materials like stones and other high density materials. The power consumed by the mill per ton of coal ground is only twothirds of the ball mills.

Dec 13, 2011· A vertical spindle mill is also designed for pressurized and suction type requirements. Boiler designers use this type of mill for poor quality coal as this type of mill rejects foreign materials like stones and other high density materials. The power consumed by the mill per ton of coal ground is only twothirds of the ball mills.

MACHINING OPERATIONS AND MACHINE TOOLS

MACHINING OPERATIONS AND MACHINE TOOLS •Turning and Related Operations •Drilling and Related Operations ... Horizontal or vertical refers to the orientation of ... spindle ©2002 John Wiley Sons, Inc. M. P. Groover, "Fundamentals of Modern Manufacturing 2/e" Figure A vertical boring mill –for large, heavy workparts ...

MACHINING OPERATIONS AND MACHINE TOOLS •Turning and Related Operations •Drilling and Related Operations ... Horizontal or vertical refers to the orientation of ... spindle ©2002 John Wiley Sons, Inc. M. P. Groover, "Fundamentals of Modern Manufacturing 2/e" Figure A vertical boring mill –for large, heavy workparts ...

Vertical Axis Wind Turbine Seminar Report and Project ...

Apr 28, 2018· Vertical Axis Wind Turbine PPT Presentation The objective of Vertical Axis Wind Turbine PPT for seminar and project is to design, build, and test composite airfoil blades for a wind turbine. The PPT briefly describes the designs, structural analysis, scale model and fabrication process.

Apr 28, 2018· Vertical Axis Wind Turbine PPT Presentation The objective of Vertical Axis Wind Turbine PPT for seminar and project is to design, build, and test composite airfoil blades for a wind turbine. The PPT briefly describes the designs, structural analysis, scale model and fabrication process.

PPT – WIND ENERGY PowerPoint presentation | free to view ...

World's Best PowerPoint Templates CrystalGraphics offers more PowerPoint templates than anyone else in the world, with over 4 million to choose from. Winner of the Standing Ovation Award for "Best PowerPoint Templates" from Presentations Magazine. They'll give your presentations a professional, memorable appearance the kind of sophisticated look that today's audiences expect.

World's Best PowerPoint Templates CrystalGraphics offers more PowerPoint templates than anyone else in the world, with over 4 million to choose from. Winner of the Standing Ovation Award for "Best PowerPoint Templates" from Presentations Magazine. They'll give your presentations a professional, memorable appearance the kind of sophisticated look that today's audiences expect.

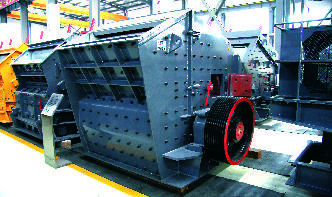

BHEL PRESENCE IN COAL MILLING EQUIPMENT

Tube mills suitable for catering to coal throughput from 30 TPH to 110 TPH. Bowl Mill is basically a vertical Mill rotating at Moderate speed (30 to 60 rpm) about its axis. It is recognized as the most advantageous design of the coal pulveriser because of its low initial cost, low maintenance cost, removal of .

Tube mills suitable for catering to coal throughput from 30 TPH to 110 TPH. Bowl Mill is basically a vertical Mill rotating at Moderate speed (30 to 60 rpm) about its axis. It is recognized as the most advantageous design of the coal pulveriser because of its low initial cost, low maintenance cost, removal of .

BANDSAW OPERATIONS Historic Naval Ships Association

Model 16120 is a floor mounting, metal cutting, vertical bandsaw machine (figure 3). It has a 16 inch throat depth, and can accommodate a saw blade or a file band. The heavy, ribbed, cast iron table is 24 x 24 inches; it can be adjusted for a tilt of 10° to the left or 45° to the right.

Model 16120 is a floor mounting, metal cutting, vertical bandsaw machine (figure 3). It has a 16 inch throat depth, and can accommodate a saw blade or a file band. The heavy, ribbed, cast iron table is 24 x 24 inches; it can be adjusted for a tilt of 10° to the left or 45° to the right.

Ball Mill RETSCH powerful grinding and homogenization

A ball mill for powerful size reduction and homogenization. They are used for the most demanding tasks, from routine sample processing to colloidal grinding and advanced materials development. The High Energy Ball Mill Emax is an entirely new type of mill for high energy input. The unique combination of high friction and impact results in extremely fine particles within the shortest amount of time.

A ball mill for powerful size reduction and homogenization. They are used for the most demanding tasks, from routine sample processing to colloidal grinding and advanced materials development. The High Energy Ball Mill Emax is an entirely new type of mill for high energy input. The unique combination of high friction and impact results in extremely fine particles within the shortest amount of time.

Milling Machines Safety ME

Mills are classified on the basis of the position of their spindle. The spindle operates in either a vertical or horizontal position. The amount of horsepower the mill is able to supply to the cutter is also often important. Mill Construction; The vertical milling machine is .

Mills are classified on the basis of the position of their spindle. The spindle operates in either a vertical or horizontal position. The amount of horsepower the mill is able to supply to the cutter is also often important. Mill Construction; The vertical milling machine is .

Power plant maintenance: BOWL MILL WORKING PRINCIPLE

Jul 10, 2016· bowl mill working principle pulveriser to dry the coal, sufficient pressure on the rolls to pulverise it, and proper setting of the classifier deflector vanes to obtain a fineness reasonably close to that for which the pulveriser was Experience will

Jul 10, 2016· bowl mill working principle pulveriser to dry the coal, sufficient pressure on the rolls to pulverise it, and proper setting of the classifier deflector vanes to obtain a fineness reasonably close to that for which the pulveriser was Experience will

HOT STRIP MILLS Mechanical Equipment SMS group

SMS DEMAG Hot Strip Mills 10 The drumtype shear installed between the roughing and finishing mills of a hot strip mill crops the transfer bar at its head and tail. In special applications, the drumtype shear also serves to divide transfer bars and finished plates. Based on the experience gained from more than 60 drumtype shears built so far,

SMS DEMAG Hot Strip Mills 10 The drumtype shear installed between the roughing and finishing mills of a hot strip mill crops the transfer bar at its head and tail. In special applications, the drumtype shear also serves to divide transfer bars and finished plates. Based on the experience gained from more than 60 drumtype shears built so far,

Types of Milling Machines | Smithy Detroit Machine Tools

Types of Milling Machines. The cutter head can be swiveled from a vertical spindle position to a horizontal spindle position or can be fixed at any desired angular position between vertical and horizontal. The saddle and knee are hand driven for vertical and cross feed adjustment while the worktable can be either hand or power driven at the operator's choice.

Types of Milling Machines. The cutter head can be swiveled from a vertical spindle position to a horizontal spindle position or can be fixed at any desired angular position between vertical and horizontal. The saddle and knee are hand driven for vertical and cross feed adjustment while the worktable can be either hand or power driven at the operator's choice.

G and M Programming for CNC Milling Machines

The Billet Definition is a feature which is only used in the Denford programming system. It defines the size of the workpiece billet for use in the simulation sections of the Denford machine software. The billet definition command has no outcome on the actual machining of the part.

The Billet Definition is a feature which is only used in the Denford programming system. It defines the size of the workpiece billet for use in the simulation sections of the Denford machine software. The billet definition command has no outcome on the actual machining of the part.

Milling Machines vs. Lathe Machines In The Loupe

For intricate parts like that, a milling machine would be required for successful machining. While lathe machines are more limited in use than a milling machine, they are superior for cylindrical parts. While a mill can make the same cuts that a lathe does, it may need multiple setups to create the same part.

For intricate parts like that, a milling machine would be required for successful machining. While lathe machines are more limited in use than a milling machine, they are superior for cylindrical parts. While a mill can make the same cuts that a lathe does, it may need multiple setups to create the same part.

Milling Machine: Alignment and Setup Procedures

Overarmtype vertical milling machines that do not have either a swiveling or fully universal head do not require head alignment because the head can move up and down only. Table Alignment The table on universal milling machine must be checked for alignment whenever it is being returned to 0˚ position or when a job involving precise angular relationships is to be done.

Overarmtype vertical milling machines that do not have either a swiveling or fully universal head do not require head alignment because the head can move up and down only. Table Alignment The table on universal milling machine must be checked for alignment whenever it is being returned to 0˚ position or when a job involving precise angular relationships is to be done.

Vertical Machining Centers (VMCs) : Modern Machine Shop

Vertical Machining Centers (VMCs) These milling machines have vertically oriented spindles that approach workpieces mounted on their table from above and commonly perform or 3axis machining operations. They are less costly than horizontal machining centers (HMCs), which makes them attractive to small job shops as well as larger machining...

Vertical Machining Centers (VMCs) These milling machines have vertically oriented spindles that approach workpieces mounted on their table from above and commonly perform or 3axis machining operations. They are less costly than horizontal machining centers (HMCs), which makes them attractive to small job shops as well as larger machining...

Milling (machining) Wikipedia

The pendant usually provides between four and eight feet of vertical movement. Some mills have a large (30" or more) integral facing head. Right angle rotary tables and vertical milling attachments are available for further flexibility. Jig borer Vertical mills that are built to bore holes, and very light slot or face milling. They are typically bed mills with a long spindle throw.

The pendant usually provides between four and eight feet of vertical movement. Some mills have a large (30" or more) integral facing head. Right angle rotary tables and vertical milling attachments are available for further flexibility. Jig borer Vertical mills that are built to bore holes, and very light slot or face milling. They are typically bed mills with a long spindle throw.

الوظائف ذات الصلة

- الفحم سحق تخطيط المصنع

- مصنع إعادة تدوير الخرسانة بالجزائر

- الحصول على رخصة تعدين الذهب للعمل في المملكة العربية السعودية

- صنع الرمال موردي المعدات

- صناعة الاسمنت العماني

- كيف يمكنني إعداد الحجر محطم في هيماشال

- كسارة تصادمية متنقلة

- التعدين المعدات اللازمة ل النحاس س إعادة

- طحن مطحنة للبيع السودان

- آلات لخام الحديد

- mineral crusher equipment for sale

- zim maize grinding mill

- canica vsi for sale

- gold concentration plant manufacturer

- coal processing crusher

- mhada mill workers lottery list date amp b price

- double jaw crushers 200 tph capacity

- wet grinder prestige price in mumbai

- pencil grinding machine

- optical stone grinding machine

معلومات عنا

واستنادا إلى استراتيجية "خدمة الترجمة"، وضعت كروشر 22 مكتبا في الخارج. إذا كان لديك أي أسئلة، يمكنك إجراء اتصالات مع مكتب قريب مباشرة. سوف كروشر نقدم لكم حلول لمشاكلك بسرعة.

Ccrusher

WhatsApp

WhatsApp