some methods of improving the performance of ball mill

Improving Grinding Efficiency with the IsaMill™

Improving Grinding Efficiency with the IsaMill™ M. Larson1, R. Morrison1, F. Shi1 and Young2 1University of Queensland, JKMRC, QLD 2Xstrata Technology, QLD Introduction, Background and Objectives As mining companies have been called on to

Improving Grinding Efficiency with the IsaMill™ M. Larson1, R. Morrison1, F. Shi1 and Young2 1University of Queensland, JKMRC, QLD 2Xstrata Technology, QLD Introduction, Background and Objectives As mining companies have been called on to

Report on Methods to Make Ball Grinder More Efficient ...

Water will be atomized and sprayed into the grinding chamber by the high pressure air, which will bring the heat out and low down the inside it is needed to spray water is depending on the ball mill inside temperature. Generally speaking, when it .

Water will be atomized and sprayed into the grinding chamber by the high pressure air, which will bring the heat out and low down the inside it is needed to spray water is depending on the ball mill inside temperature. Generally speaking, when it .

Grinding in Ball Mills: Modeling and Process Control ...

The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills. Basic kinetic and energy models of the grinding process are described and the most commonly used control strategies are analyzed and discussed.

The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills. Basic kinetic and energy models of the grinding process are described and the most commonly used control strategies are analyzed and discussed.

Process equipment Our equipment / Mills

Ball mills can be designed to operate continuously (fed at one end of the system and discharged at the other), or on a batch basis for smaller, or intermittent volumes. They can also be operated either on a standalone basis ('opencircuit grinding') or in conjunction with a classifier which returns oversize product to the mill for further ...

Ball mills can be designed to operate continuously (fed at one end of the system and discharged at the other), or on a batch basis for smaller, or intermittent volumes. They can also be operated either on a standalone basis ('opencircuit grinding') or in conjunction with a classifier which returns oversize product to the mill for further ...

power calculation for ball mills

effects of grinding media shapes on ball mill performance terms of energy requirements and steel consumption related to grinding media ... The Power Consumption Calculation of a Ball Drum Mill Current methods of power consumption calculation of a mill drive do not allow determining the power consumption for ball drum mills with ...

effects of grinding media shapes on ball mill performance terms of energy requirements and steel consumption related to grinding media ... The Power Consumption Calculation of a Ball Drum Mill Current methods of power consumption calculation of a mill drive do not allow determining the power consumption for ball drum mills with ...

How to Improve the Production of Ball Mills?

But currently there are some shortcomings existing in ball mill grinder such as the low production output and the large power consumption, so how to improve the yield of ball mill machine is the ...

But currently there are some shortcomings existing in ball mill grinder such as the low production output and the large power consumption, so how to improve the yield of ball mill machine is the ...

Joyal China Supplier High Efficiency Ball Mill Limestone ...

Joyal China supplier high efficiency ball mill limestone ball mill prices is the key equipment for secondary grinding after crushing. And it is suitable for grinding all kinds of ores and other materials, no matter wet grinding or dry grinding.

Joyal China supplier high efficiency ball mill limestone ball mill prices is the key equipment for secondary grinding after crushing. And it is suitable for grinding all kinds of ores and other materials, no matter wet grinding or dry grinding.

A Method to Determine the Ball Filling, in Miduk Copper ...

ball mills. These characteristics make SAG mills an excellent example of critical equipments whose continuous and stable operation is essential to guarantee mineral processing plant profitability [1]. To achieve improvements in the production capacity and energy .

ball mills. These characteristics make SAG mills an excellent example of critical equipments whose continuous and stable operation is essential to guarantee mineral processing plant profitability [1]. To achieve improvements in the production capacity and energy .

Model Predictive Control for SAG Milling in Minerals ...

Model Predictive Control on a SAG Mill and Ball Mills The solution for the SAG Mill is an adaptive controller which controls mill load using direct mill weight .

Model Predictive Control on a SAG Mill and Ball Mills The solution for the SAG Mill is an adaptive controller which controls mill load using direct mill weight .

Grinding Aids for Cement SlideShare

May 11, 2015· a grinding mill which consumes 6070% of the total electricity consumption of the cement plant[12]. A grinding mill (Ball Mill) is used to grind the cement clinker into fine cement powder. Grinding Aids are used to improve the grinding efficiency and reduce power consumption. This paper discusses the grinding aids mechanism and

May 11, 2015· a grinding mill which consumes 6070% of the total electricity consumption of the cement plant[12]. A grinding mill (Ball Mill) is used to grind the cement clinker into fine cement powder. Grinding Aids are used to improve the grinding efficiency and reduce power consumption. This paper discusses the grinding aids mechanism and

MEASURING THE EFFICIENCY OF THE TUMBLING MILL AS A ...

Predicted power draw versus mill speeds at 60% mill speed and 50% mill load. .....74 Figure The steadystate charge profiles of the 1m mill with (4 x 4 cm) lifters, 35% ball

Predicted power draw versus mill speeds at 60% mill speed and 50% mill load. .....74 Figure The steadystate charge profiles of the 1m mill with (4 x 4 cm) lifters, 35% ball

Optimum revolution and rotational directions and their ...

Dec 10, 2004· 1. Introduction. A planetary ball mill is known to install pots on a disk, and both are rotated simultaneously and separately at high speed. Such highspeed rotation of both the pot and the disk makes the balls to move strongly and violently, leading to large impact energy of balls that improves grinding performance.

Dec 10, 2004· 1. Introduction. A planetary ball mill is known to install pots on a disk, and both are rotated simultaneously and separately at high speed. Such highspeed rotation of both the pot and the disk makes the balls to move strongly and violently, leading to large impact energy of balls that improves grinding performance.

Ball Milling FAQ Newbie Questions Forum

It is potentially faster than a ball mill to make black powder, or other compositions. They are also useful to powder small amounts of chemicals. It has the disadvantage that it is extremely labor intensive relative to a ball mill. CIA Method – This is done by rapidly precipitating out KNO3 with cold alcohol in the presence of charcoal and sulfur. This may be the fastest overall method to make black powder.

It is potentially faster than a ball mill to make black powder, or other compositions. They are also useful to powder small amounts of chemicals. It has the disadvantage that it is extremely labor intensive relative to a ball mill. CIA Method – This is done by rapidly precipitating out KNO3 with cold alcohol in the presence of charcoal and sulfur. This may be the fastest overall method to make black powder.

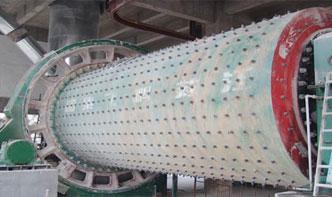

Ball Mill Machine For Sale FTM Machinery

The ball mill is a milling equipment used to grind various materials and produce ore pulp, which uses steel balls as the grinding medium. According to different grinding methods, Ball mill can be divided into the dry and wet ways. In general, we adopt the wet grinding method for the ore dressing.

The ball mill is a milling equipment used to grind various materials and produce ore pulp, which uses steel balls as the grinding medium. According to different grinding methods, Ball mill can be divided into the dry and wet ways. In general, we adopt the wet grinding method for the ore dressing.

Determination and scaleup of the milling parameters of a ...

to determine the milling parameters using pearshaped ball mill. Twelve mono sized fractions of an oxidised coppercobalt ore sample were prepared and wet ground batch wise using a laboratoryscale ball mill at the University of Lubumbashi: 6700 + 4750, 4750 +

to determine the milling parameters using pearshaped ball mill. Twelve mono sized fractions of an oxidised coppercobalt ore sample were prepared and wet ground batch wise using a laboratoryscale ball mill at the University of Lubumbashi: 6700 + 4750, 4750 +

Selection Criteria for Grinding Balls

Selection Criteria for Grinding Balls Jan 10, 2018 Coal machine generally use 60mm Grinding Ball, we can select steel grinding balls according to the following criteria: general is the overall hardness of grinding ball is high, better wearresistant performance, not easy to lose and broken, the impact toughness is good.

Selection Criteria for Grinding Balls Jan 10, 2018 Coal machine generally use 60mm Grinding Ball, we can select steel grinding balls according to the following criteria: general is the overall hardness of grinding ball is high, better wearresistant performance, not easy to lose and broken, the impact toughness is good.

ball mill inspection method

Ball mill Wikipedia. Chinese. ensp·enspA ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium.

Ball mill Wikipedia. Chinese. ensp·enspA ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium.

Model Predictive Control for SAG Milling in Minerals ...

Model Predictive Control for SAG Milling in Minerals Processing | 5 Model Predictive Control on a SAG Mill and Ball Mills The solution for the SAG Mill is an adaptive controller which controls mill load using direct mill weight measurement or indirectly from bearing oil pressure.

Model Predictive Control for SAG Milling in Minerals Processing | 5 Model Predictive Control on a SAG Mill and Ball Mills The solution for the SAG Mill is an adaptive controller which controls mill load using direct mill weight measurement or indirectly from bearing oil pressure.

Testing method for ball mills Outokumpu Technology Oyj

Apr 03, 2007· A testing method for designing a semiautogenous or an autogenous grinding circuit having at least one ball mill for grinding ore, the method comprising: measuring an amount of time for grinding a predetermined mass of ore to a first predetermined size, in a first, semiautogenous step; calculating a required grinding energy based on the measured time for grinding in the first step, mass of ore, mill .

Apr 03, 2007· A testing method for designing a semiautogenous or an autogenous grinding circuit having at least one ball mill for grinding ore, the method comprising: measuring an amount of time for grinding a predetermined mass of ore to a first predetermined size, in a first, semiautogenous step; calculating a required grinding energy based on the measured time for grinding in the first step, mass of ore, mill .

الوظائف ذات الصلة

- تستخدم مطحنة ريمون القديمة الأسطوانية في مصر

- قائمة أسعار طاحونة الرطب الجدول أعلى في مصر

- تهتز آلة فحص لل الجرانيت

- تكلفة شراء الباريت مطحنة

- المشاريع وتطوير حجر سحق آلة

- آلات كسارة برينسيب العمل

- آلة تكسير الحجارة المصنوعة في الجزائر

- كيف تعمل غسالة الرمل

- إنتاج مسحوق البنتونيت خط

- المعدات بالغسل الذهب المملكة العربية السعودية

- م والرمل صنع آلة صغيرة

- mobile crushing plants in nigeria for sale

- kind of magnetic separation

- walk behind sand sifter

- peralatan crusher di afrika selatan

- legal rules to establish a stone crusher

- packing tape

- bad mining villages in ghana

- digunakan granit crusher untuk dijual

- moisture meter for crushed coal pile mc 7825s

معلومات عنا

واستنادا إلى استراتيجية "خدمة الترجمة"، وضعت كروشر 22 مكتبا في الخارج. إذا كان لديك أي أسئلة، يمكنك إجراء اتصالات مع مكتب قريب مباشرة. سوف كروشر نقدم لكم حلول لمشاكلك بسرعة.

Ccrusher

WhatsApp

WhatsApp