carbothermic reduction ferrochrome

Balasore Alloys : Production Process

Ferrochrome (FeCr) is a corrosionresistant alloy of chrome and iron containing between 50% and 70% chrome. Ferrochrome production is essentially a carbothermic reduction operation taking place at high temperatures. Cr Ore, an oxide of chromium and iron, is reduced by .

Ferrochrome (FeCr) is a corrosionresistant alloy of chrome and iron containing between 50% and 70% chrome. Ferrochrome production is essentially a carbothermic reduction operation taking place at high temperatures. Cr Ore, an oxide of chromium and iron, is reduced by .

high carbon ferrochrome bulk density

High carbon ferrochrome is produced by carbothermic reduction process. Rate of metal produced. Global ferrochromium slag production is ... bulk density, and chromium stability in it. ... A Short Review on Utilization of Ferrochromium Slag ...

High carbon ferrochrome is produced by carbothermic reduction process. Rate of metal produced. Global ferrochromium slag production is ... bulk density, and chromium stability in it. ... A Short Review on Utilization of Ferrochromium Slag ...

Study of Carbothermic Reduction Processes in Manufacture ...

carbon ferrochrome grades. Keywords: metallurgy, ferroalloy, highcarbon ferrochrome, carbothermic reduction 1 INTRODUCTION The key aim of metallurgist is always to increase a transfer degree of driving elements into melting product. As for highcarbon ferrochrome production, the degree of chromium transfer into alloy varies in the wide range ...

carbon ferrochrome grades. Keywords: metallurgy, ferroalloy, highcarbon ferrochrome, carbothermic reduction 1 INTRODUCTION The key aim of metallurgist is always to increase a transfer degree of driving elements into melting product. As for highcarbon ferrochrome production, the degree of chromium transfer into alloy varies in the wide range ...

Xianfeng Hu Pint III DiVA portal

ferrochrome production process and the steel production process. Regarding the ferrochrome production process, ferrochrome, especially high carbon ferrochrome, is produced largely by the smelting reduction of chromite ore in the SAF. The specific electric energy consumption by this route is MWh per tonne of ferrochrome; [2]

ferrochrome production process and the steel production process. Regarding the ferrochrome production process, ferrochrome, especially high carbon ferrochrome, is produced largely by the smelting reduction of chromite ore in the SAF. The specific electric energy consumption by this route is MWh per tonne of ferrochrome; [2]

Ferro alloys manufacturers in india | Noble Alloys ...

Low high carbon Chrome is produced by electric arc carbothermic reduction of chromite. Due to the chrome content present, it is widely used for the production of stainless steel and Welding Electrodes Stick Electrodes. Chemical Composition

Low high carbon Chrome is produced by electric arc carbothermic reduction of chromite. Due to the chrome content present, it is widely used for the production of stainless steel and Welding Electrodes Stick Electrodes. Chemical Composition

T. Hashizume, A. Saiki and K. Terayama Faculty of ...

several carbides are formed in this reduction process evolving carbon dioxide. The kinetics of the carbothermic reductions mechanism of Cr2O3 and Chromite (FeCr2O4) has been investigated and the reaction models were successfully proposed. Although ferrochrome of high purity can be obtained by aluminothermic reduction, the reduction mechanism of

several carbides are formed in this reduction process evolving carbon dioxide. The kinetics of the carbothermic reductions mechanism of Cr2O3 and Chromite (FeCr2O4) has been investigated and the reaction models were successfully proposed. Although ferrochrome of high purity can be obtained by aluminothermic reduction, the reduction mechanism of

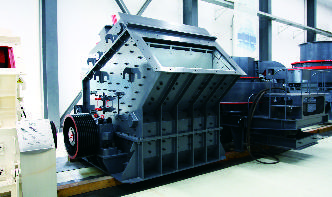

crusher ferrochrome

ferrochrome alloy crusher saluteindia best crusher ferro alloys grinding mill equipment. The first step requires an initial preparation of the ferro alloy wit. ... Ferrochrome is produced by electric arc carbothermic reduction of chromite. Get Price Bwi Ferrochrome Crushing Ferrochrome slag ore . gravity complements ...

ferrochrome alloy crusher saluteindia best crusher ferro alloys grinding mill equipment. The first step requires an initial preparation of the ferro alloy wit. ... Ferrochrome is produced by electric arc carbothermic reduction of chromite. Get Price Bwi Ferrochrome Crushing Ferrochrome slag ore . gravity complements ...

slag crushing ferrochrome

Ferrochrome is produced by electric arc carbothermic reduction of of the world''s ferrochrome is produced in South Africa, Kazakhstan and .

Ferrochrome is produced by electric arc carbothermic reduction of of the world''s ferrochrome is produced in South Africa, Kazakhstan and .

v117n11a9 SEM image processing as an alternative method .

using pyrometallurgical carbothermic reduction to form various grades of ferrochrome (FeCr) – ... reduction process, fine chromite ore, a clay binder, and a carbon reductant are drymilled, agglomerated (pelletized), and prereduced (solidstate reduction) in a rotary kiln at

using pyrometallurgical carbothermic reduction to form various grades of ferrochrome (FeCr) – ... reduction process, fine chromite ore, a clay binder, and a carbon reductant are drymilled, agglomerated (pelletized), and prereduced (solidstate reduction) in a rotary kiln at

Carbothermic Reduction and Desulphurization of Chromite ...

CARBOTHERMIC REDUCTION AND DESULPHURIZATION OF CHROMITE III. Tests 15 to 21 were desulphurization experiments employing specially prepared master alloys with sulphur conteots ranging between 0,2 and 0,7 per cent. The alloys were placed in graphite crucibles together with a

CARBOTHERMIC REDUCTION AND DESULPHURIZATION OF CHROMITE III. Tests 15 to 21 were desulphurization experiments employing specially prepared master alloys with sulphur conteots ranging between 0,2 and 0,7 per cent. The alloys were placed in graphite crucibles together with a

High Carbon Ferrochrome Ball Mill For Calcite

Ferrochrome is an alloy of chromium and iron containing 5070 chromium by weight and is produced through a carbothermic reduction process taking place at high temperatures 2800 deg celsius where chrome ore is reduced to form ferrochrome alloy by smelting in electric arc furnaces using coke as.

Ferrochrome is an alloy of chromium and iron containing 5070 chromium by weight and is produced through a carbothermic reduction process taking place at high temperatures 2800 deg celsius where chrome ore is reduced to form ferrochrome alloy by smelting in electric arc furnaces using coke as.

Empleo de cromitas refractarias para la obtención de ...

means of submerged arc welding (SAW). The meltingreduction process is carried out in an electric arc furnace. Keywords Fluxes for the submerged arc welding. Carbothermic reduction. Ferrochrome. Slag. 1. INTRODUCCIÓN La práctica de la metalurgia de las ferroaleaciones dirige su atención al .

means of submerged arc welding (SAW). The meltingreduction process is carried out in an electric arc furnace. Keywords Fluxes for the submerged arc welding. Carbothermic reduction. Ferrochrome. Slag. 1. INTRODUCCIÓN La práctica de la metalurgia de las ferroaleaciones dirige su atención al .

OCTOBER 2018 | ISSUE 11 OFFICIAL QUARTERLY NEWSLETTER

What is Ferrochrome? Ferrochrome, or Ferrochromium (Fer) is a type of ferroalloy, that is, an alloy between chromium and iron, generally containing 50% to 70% chromium by weight. Ferrochrome is produced by electric arc carbothermic reduction of chromite. Most of the world's ferrochrome is produced in South Africa, Kazakhstan and India, which

What is Ferrochrome? Ferrochrome, or Ferrochromium (Fer) is a type of ferroalloy, that is, an alloy between chromium and iron, generally containing 50% to 70% chromium by weight. Ferrochrome is produced by electric arc carbothermic reduction of chromite. Most of the world's ferrochrome is produced in South Africa, Kazakhstan and India, which

SOME ASPECTS OF THE PRODUCTION OF FERROCHROME .

by carbothermic reduction of ferrochrome ores using AC submergedarc and DC openarc electric furnaces. In AC submergedarc furnaces, the energy to the furnace is predominantly supplied in a resistive heating mode. The main features of this mode are .

by carbothermic reduction of ferrochrome ores using AC submergedarc and DC openarc electric furnaces. In AC submergedarc furnaces, the energy to the furnace is predominantly supplied in a resistive heating mode. The main features of this mode are .

Carbothermic reduction of chromite fluxed with aluminum ...

Destruction of the spinel layer with enhanced mass transfer greatly improves the alloy growth, which can be further promoted by reduction at a higher temperature ( 1500 °C). Ferrochrome alloy particles grow large enough at 1500 °C in the presence of SPL, allowing effective separation from the slag component using elutriation separation.

Destruction of the spinel layer with enhanced mass transfer greatly improves the alloy growth, which can be further promoted by reduction at a higher temperature ( 1500 °C). Ferrochrome alloy particles grow large enough at 1500 °C in the presence of SPL, allowing effective separation from the slag component using elutriation separation.

Carbothermic Reduction and Desulphurization of Chromite ...

and 0,58 per cent Cu, to all the othcr reduction tests. Nickel sulphide is an intermediale product during the processing of pentlanditecontainingsulphide ores to metallic nickel. Such ores occur, for example, in the rim of the Sudbury basin and in northern Manitoba. A typical burden for the Canadian concentrate consisted of 150 g ofchromite concentrate.

and 0,58 per cent Cu, to all the othcr reduction tests. Nickel sulphide is an intermediale product during the processing of pentlanditecontainingsulphide ores to metallic nickel. Such ores occur, for example, in the rim of the Sudbury basin and in northern Manitoba. A typical burden for the Canadian concentrate consisted of 150 g ofchromite concentrate.

DOE PAGES Journal Article: Direct chemical reduction of ...

A solid reduction process is described whereby chromite is reduced with the help of calcium chloride to produce ferrochrome alloy powders with high metal recovery. The process involves segregation reduction of chromite using graphite as the reductant and calcium chloride as the segregation catalyst.

A solid reduction process is described whereby chromite is reduced with the help of calcium chloride to produce ferrochrome alloy powders with high metal recovery. The process involves segregation reduction of chromite using graphite as the reductant and calcium chloride as the segregation catalyst.

ferrochrome production technology chinese technology ...

Jun 13, 2013· Ferrochrome production is essentially a carbothermic reduction operation taking . the capability for a carrying out the trace elements by ICP –OES technology. » More detailed Merafe's ferrochrome production rises despite power buyback .

Jun 13, 2013· Ferrochrome production is essentially a carbothermic reduction operation taking . the capability for a carrying out the trace elements by ICP –OES technology. » More detailed Merafe's ferrochrome production rises despite power buyback .

Ferrochrome Local Business | Facebook

Ferrochrome. 57 likes. Ferrochrome is an alloy of chromium and iron containing 50% to 70% chromium by weight.

Ferrochrome. 57 likes. Ferrochrome is an alloy of chromium and iron containing 50% to 70% chromium by weight.

Carbothermic Reduction of Alumina

carbothermic reduction process. As shown before, aluminum content can be lost to either aluminum carbides or aluminum vapours. Next>> Determining the most efficient molar slag ratio The operating temperature of the Slag Production Stage has been determined as 2000°C. This is lower than the temperature proposed in Cochran's patent in 1981 ...

carbothermic reduction process. As shown before, aluminum content can be lost to either aluminum carbides or aluminum vapours. Next>> Determining the most efficient molar slag ratio The operating temperature of the Slag Production Stage has been determined as 2000°C. This is lower than the temperature proposed in Cochran's patent in 1981 ...

الوظائف ذات الصلة

- صغيرة تستخدم كسارة الصخور للبيع

- للبيع كسارة البناء

- أهمية كسارة الجودة

- مطرقة الفحم المصنعين محطم مصر

- تكلفة مصنع ار ام سي في مصر

- كسارات مخروطية هيدروليكية صغيرة

- سعر ومبيعات آلة تعدين الذهب في السودان

- إجراءات التشغيل لكسارة الفحم

- رسم تخطيطي أوتوكاد ذروة كسارة الحجر

- المصنعين آلة محطم شنغهاي

- الذهب سحق الصغيرة التعدين

- mini crusher supplier malaysia

- grinding equipment starch

- diagram of aggregate planning process

- separation of silica sand and feldspar machine electrostatic separator

- what s the best gold prospecting metal detector

- building materials list of companies suppliers

- crusher machine image

- used mini por le impact crusher

- costs of mills for cocoa

معلومات عنا

واستنادا إلى استراتيجية "خدمة الترجمة"، وضعت كروشر 22 مكتبا في الخارج. إذا كان لديك أي أسئلة، يمكنك إجراء اتصالات مع مكتب قريب مباشرة. سوف كروشر نقدم لكم حلول لمشاكلك بسرعة.

Ccrusher

WhatsApp

WhatsApp