cement ball mills media chemical composition

Cement Ball Mill Bailing Machinery

Cement ball mill mainly consists of feed port, bearing outer gland, bearing, bearing gland, bearing inner gland, feed grinding head, slate, small lining, large lining, cylinder, flower board, big gear, out The material is composed of a material inlet, a bearing base, a grinding end grinding head and a bracket.

Cement ball mill mainly consists of feed port, bearing outer gland, bearing, bearing gland, bearing inner gland, feed grinding head, slate, small lining, large lining, cylinder, flower board, big gear, out The material is composed of a material inlet, a bearing base, a grinding end grinding head and a bracket.

Cement Ball Mill_Ball Mill,Ball Mill Supplier,Ball Mill ...

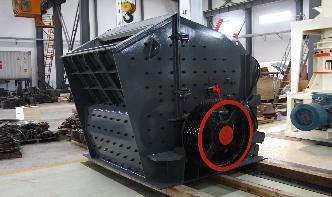

A cement mill is the equipment that used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills. Cement clinker is usually ground using a cement ball mill. This is essentially a large rotating drum containing grinding media normally steel balls.

A cement mill is the equipment that used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills. Cement clinker is usually ground using a cement ball mill. This is essentially a large rotating drum containing grinding media normally steel balls.

Quick and Easy Black Powder Ball Mill — Skylighter, Inc.

Quick Easy Black Powder Ball Mill. Ball mills are also used in pyrotechnics and the manufacture of black powder, but cannot be used in the preparation of some pyrotechnic mixtures such as flash powder because of their sensitivity to impact. Highquality ball mills are potentially expensive and can grind mixture particles to as small as 5 nm,...

Quick Easy Black Powder Ball Mill. Ball mills are also used in pyrotechnics and the manufacture of black powder, but cannot be used in the preparation of some pyrotechnic mixtures such as flash powder because of their sensitivity to impact. Highquality ball mills are potentially expensive and can grind mixture particles to as small as 5 nm,...

grinding media steel balls for cement mills in europe

Forged Casting Steel Grinding Mining Balls for Coal Cement Mills Media Grinding Balls. ... Cast Steel Grinding Balls for cement plant. Get Price. TOYO Grinding Ball Co.,LTD 10 may 2017. The PREFERRED global grinding media supplier ... The only high chrome grinding ball manufacturer in the world to use ... the optimization of raw/cement mills.

Forged Casting Steel Grinding Mining Balls for Coal Cement Mills Media Grinding Balls. ... Cast Steel Grinding Balls for cement plant. Get Price. TOYO Grinding Ball Co.,LTD 10 may 2017. The PREFERRED global grinding media supplier ... The only high chrome grinding ball manufacturer in the world to use ... the optimization of raw/cement mills.

Composition In Grinding Media Balls

Cement Ball Mill Grinding Media Chemical Composition,US 700 1,200 / Ton, Shandong, China (Mainland), TITLE, from Zhangqiu Taitou Special Steel Ball ... Grinding Media | Glen Mills Grinding Media is used to finely grind ore material to a size which allows ...

Cement Ball Mill Grinding Media Chemical Composition,US 700 1,200 / Ton, Shandong, China (Mainland), TITLE, from Zhangqiu Taitou Special Steel Ball ... Grinding Media | Glen Mills Grinding Media is used to finely grind ore material to a size which allows ...

Used Ball Mills | Ball Mills for Sale | Phoenix Equipment

Used, unused and refurbished ball mills available for a fraction of the cost of new. USbased Phoenix Equipment is a global buyer seller of ball mills, as well as other industrial equipment. Check out our extensive inventory or talk to a knowledgeable representative today.

Used, unused and refurbished ball mills available for a fraction of the cost of new. USbased Phoenix Equipment is a global buyer seller of ball mills, as well as other industrial equipment. Check out our extensive inventory or talk to a knowledgeable representative today.

Advanced process control for the cement industry

Ball mill application Ball mill grinding is a highly energy consuming process and the ECS/ProcessExpert Ball mill application is built to meet the increasing demand for maximum production with minimum power consumption while minimizing variations in quality. Benefits • 3Up to 6% increase in production • Up to 4% reduction in ball mill specific

Ball mill application Ball mill grinding is a highly energy consuming process and the ECS/ProcessExpert Ball mill application is built to meet the increasing demand for maximum production with minimum power consumption while minimizing variations in quality. Benefits • 3Up to 6% increase in production • Up to 4% reduction in ball mill specific

cement process by ball mill

A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills .... are now increasingly popular as a "pregrind" process, with the cement finished in a single chamber ball mill.

A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills .... are now increasingly popular as a "pregrind" process, with the cement finished in a single chamber ball mill.

Cement Chemistry The Concrete Portal

The method of grinding cement may also influence the hydration kinetics. Cements ground in high pressure roller mills set faster than in ball mills, because of higher reactivity of C 3 A and C 3 S phases, and a lowered rate of decomposition of CaSO 4. Figure 2: Progress of cement hydration. Composition .

The method of grinding cement may also influence the hydration kinetics. Cements ground in high pressure roller mills set faster than in ball mills, because of higher reactivity of C 3 A and C 3 S phases, and a lowered rate of decomposition of CaSO 4. Figure 2: Progress of cement hydration. Composition .

CONTROL, OPTIMIZATION AND MONITORING OF PORTLAND .

developed to model relationship among cement mill operational parameters. The response variable was weight percentage of product residue on 32micrometer sieve (or fineness), while the input parameters were revolution percent, falofon percentage, and the elevator amperage (amps), which exhibits elevator charge to the separator.

developed to model relationship among cement mill operational parameters. The response variable was weight percentage of product residue on 32micrometer sieve (or fineness), while the input parameters were revolution percent, falofon percentage, and the elevator amperage (amps), which exhibits elevator charge to the separator.

CONDITIONS OF SAMPLE PREPARATION FOR QUANTITATIVE .

cause variability of chemical and mineral composition of cement. A substantial amount of effort is put into processing in the cement industry, such as minimizing the vari ... carbide disc mill or planetary ball mill equipped with stainlesssteel vials and balls for dry processing. Clin

cause variability of chemical and mineral composition of cement. A substantial amount of effort is put into processing in the cement industry, such as minimizing the vari ... carbide disc mill or planetary ball mill equipped with stainlesssteel vials and balls for dry processing. Clin

Hykrom Grinding Media Balls For The Cement And Mining Industry

Grinding media cement utility mining hykrom grinding media balls for the cement and mining cement industry grinding media aid grinding media cement batu alumina ball mill batu ball grinding ball is one ideal ball mill grinding media it can improve alumina balls.

Grinding media cement utility mining hykrom grinding media balls for the cement and mining cement industry grinding media aid grinding media cement batu alumina ball mill batu ball grinding ball is one ideal ball mill grinding media it can improve alumina balls.

Electrolytic Aluminum Catalyst Ceramic High Alumina Ball

Electrolytic aluminum catalyst ceramic high Alumina ball. Product Introduction: The product is widely used in precision processing and deep processing of various ceramics,enamels, glasses and hard materials in chemical factories,as grinding media for fine crushing machines like ball mills, cantype mills and vibration composition and physical properties.

Electrolytic aluminum catalyst ceramic high Alumina ball. Product Introduction: The product is widely used in precision processing and deep processing of various ceramics,enamels, glasses and hard materials in chemical factories,as grinding media for fine crushing machines like ball mills, cantype mills and vibration composition and physical properties.

Holderbank Cement Engineering Book

effect of cement mill temperature on cement properties Journal of Engineering Effect of Variation in Temperature on Some . Full text of "Holderbank Cement engineering book" Full text of "Holderbank Cement engineering .

effect of cement mill temperature on cement properties Journal of Engineering Effect of Variation in Temperature on Some . Full text of "Holderbank Cement engineering book" Full text of "Holderbank Cement engineering .

(PDF) A comparison of wear rates of ball mill grinding media

The Ball Mill Abrasion (BMA) test was developed by the University of Queensland Materials Performance group to simulate the high stress abrasion conditions experienced in production ball mills.

The Ball Mill Abrasion (BMA) test was developed by the University of Queensland Materials Performance group to simulate the high stress abrasion conditions experienced in production ball mills.

What is the difference between vertical mill and ball mill?

(Ball mills are limited by their larger steel ball diameters and can only be used with smaller raw materials.) 7. The product has fine adjustment of fineness, uniform particle size and stable chemical composition. (The proportion of fine powder in the product produced by the ball mill is low.)

(Ball mills are limited by their larger steel ball diameters and can only be used with smaller raw materials.) 7. The product has fine adjustment of fineness, uniform particle size and stable chemical composition. (The proportion of fine powder in the product produced by the ball mill is low.)

Ball Milling Media | Products Suppliers | Engineering360

A highenergy ball mill is one that uses a hardened vial, typically steel, and ball milling media, either steel or ceramic, to MA a sample. Piezoelectric Nanomaterials for Biomedical Applications It consists in preparing a slurry of TiO2 nanoparticles with aqueous solution of ZrO(NO3)2 and Pb(NO3)2 with zirconia ball mill media, followed by precipitation with NH4(OH) as precipitant during milling.

A highenergy ball mill is one that uses a hardened vial, typically steel, and ball milling media, either steel or ceramic, to MA a sample. Piezoelectric Nanomaterials for Biomedical Applications It consists in preparing a slurry of TiO2 nanoparticles with aqueous solution of ZrO(NO3)2 and Pb(NO3)2 with zirconia ball mill media, followed by precipitation with NH4(OH) as precipitant during milling.

Milling Media Ball Mill Grinding Media Grinding ...

Hmm, it's a tough call. Our customers have raved about the performance of our ceramic grinding media and our steel balls in vertical and horizontal mills like Chicago Boiler Red Head and Dyno mills. They also excel in /Drais, Netzsch, and Premier mills. And in Moorehouse–Cowles, Hockmeyer, and Eiger mills—just to name a few.

Hmm, it's a tough call. Our customers have raved about the performance of our ceramic grinding media and our steel balls in vertical and horizontal mills like Chicago Boiler Red Head and Dyno mills. They also excel in /Drais, Netzsch, and Premier mills. And in Moorehouse–Cowles, Hockmeyer, and Eiger mills—just to name a few.

Cement ball mill spare parts upgrade and replacement

The ball mills of Great Wall Machinery (CHAENG) are used in wellknown cement enterprises at home and abroad such as Xinjiang Tianshan Group and Henan Mengdian Group. The matching ball mill trunnion are all produced by Great Wall Cast Steel (CHAENG).

The ball mills of Great Wall Machinery (CHAENG) are used in wellknown cement enterprises at home and abroad such as Xinjiang Tianshan Group and Henan Mengdian Group. The matching ball mill trunnion are all produced by Great Wall Cast Steel (CHAENG).

Cement making process

Portland cement is the basic ingredient of concrete. Concrete is formed when portland cement creates a paste with water that binds with sand and rock to is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredients.

Portland cement is the basic ingredient of concrete. Concrete is formed when portland cement creates a paste with water that binds with sand and rock to is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredients.

Ball Charge For Cement Mills

Ball Mill For Dry Grinding Cement Ball Charge Too Coarse » alumina grinding ball for ball mill » ball mill ball chargers » chemical composition of steel grinding ... Read more how can i calculate optimum charge for cement mill BINQ ...

Ball Mill For Dry Grinding Cement Ball Charge Too Coarse » alumina grinding ball for ball mill » ball mill ball chargers » chemical composition of steel grinding ... Read more how can i calculate optimum charge for cement mill BINQ ...

الوظائف ذات الصلة

- VSI محطم طريقة عملية

- كسارة مخروطية تستخدم في خط إنتاج الحجر والحصى

- ماكينات تصنيع رمل روبو

- مصنع معالجة الذهب المحمول في الجزائر

- واحدة سوبر الرسم تصنيع الفوسفات

- تستخدم آلة تكسير الحجارة في الإمارات العربية المتحدة

- طريقة الكسارة المخروطية

- الفحم المحمول الفك محطم الموردين مصر

- رسم تخطيطي لكسارات الحجر في المحاجر

- الفك محطم الصانع سي نت

- plant layout of cement factory ppt

- mini cement plant in pakistan

- corrugated rear mill rolls

- baris crushin dari tambang bijih besi uganda

- used jaw crushers for sale inherlands

- milling machine lelong

- benefication plant of bauxite

- pt beraucoal coal mining

- used rock crusher plant and price

- para chancadora aceite

معلومات عنا

واستنادا إلى استراتيجية "خدمة الترجمة"، وضعت كروشر 22 مكتبا في الخارج. إذا كان لديك أي أسئلة، يمكنك إجراء اتصالات مع مكتب قريب مباشرة. سوف كروشر نقدم لكم حلول لمشاكلك بسرعة.

Ccrusher

WhatsApp

WhatsApp