extraction and crushing process in cement

Chemical Extraction and Mechanical Crushing Method for ...

The basic mechanism of the recycling process is extraction of calcium from a hydrated cement component, which reacts readily with acid. Calcium extraction would be effective in promoting the separation of hydrated cement from aggregates.

The basic mechanism of the recycling process is extraction of calcium from a hydrated cement component, which reacts readily with acid. Calcium extraction would be effective in promoting the separation of hydrated cement from aggregates.

Selecting and using raw materials for cement manufacture

Course Introduction and approach A new, instant access, online course, comprising of 14 lectures covering all aspects of raw material exploration, planning, extraction and preparation for use as cement clinker kiln feed.. The course is open to all in the cement industry and a fee will be charged for each student, with discounts offered to group bookings.

Course Introduction and approach A new, instant access, online course, comprising of 14 lectures covering all aspects of raw material exploration, planning, extraction and preparation for use as cement clinker kiln feed.. The course is open to all in the cement industry and a fee will be charged for each student, with discounts offered to group bookings.

process of crushing coal in cement plant

process of crushing coal in cement plant. has many years manufacturing experience in coal crushing plant (coal crushing process, washing plant and belt conveyor) is a major coal crusher supplier for power plants and coke ovens, crushing limestone for blast furnaces, and crushing a wide range of raw and manufactured materials for industry. Get More

process of crushing coal in cement plant. has many years manufacturing experience in coal crushing plant (coal crushing process, washing plant and belt conveyor) is a major coal crusher supplier for power plants and coke ovens, crushing limestone for blast furnaces, and crushing a wide range of raw and manufactured materials for industry. Get More

5 Aggregate Production

CRUSHING The first step of processing begins after the extraction from quarry or pit. Many of these steps also are common to recycled materials, clay, and other manufactured aggregates. The first stag e in most operations is the reduction and sizing by crushing. Some operations, however, provide a step prior to crushing called scalping.

CRUSHING The first step of processing begins after the extraction from quarry or pit. Many of these steps also are common to recycled materials, clay, and other manufactured aggregates. The first stag e in most operations is the reduction and sizing by crushing. Some operations, however, provide a step prior to crushing called scalping.

extraction crushing and grinding

Cement Extraction and processing: Raw materials employed in the There are four stages in the manufacture of portland cement: (1) crushing and grinding Cement Crushing Grinding Plant, In cement mining, you need to choose suitable cement grinding mill and In cement production process, cement crusher is very important since most of the raw

Cement Extraction and processing: Raw materials employed in the There are four stages in the manufacture of portland cement: (1) crushing and grinding Cement Crushing Grinding Plant, In cement mining, you need to choose suitable cement grinding mill and In cement production process, cement crusher is very important since most of the raw

Products Stationary Crushers_list

extraction of lime stone process for cement. limestone extraction and grinding is manufactured from shanghai xuanshi,it is the main mineral processing solutions .extraction of .

extraction of lime stone process for cement. limestone extraction and grinding is manufactured from shanghai xuanshi,it is the main mineral processing solutions .extraction of .

extraction crushing and grinding

The crushing and grinding process will produce a ... separation or chemical extraction are returned to the crushing or the ... crushing and grinding of platinum ore Development of PGMs and Chrome Extraction Circuit from UG–2 Ore. platinum group metals (PGM) deposit in the world.

The crushing and grinding process will produce a ... separation or chemical extraction are returned to the crushing or the ... crushing and grinding of platinum ore Development of PGMs and Chrome Extraction Circuit from UG–2 Ore. platinum group metals (PGM) deposit in the world.

crushing process in cement plants

crushing process in cement plants elixirindiacoin Cement, or Portland cement, is defined as "a hydraulic cement, obtained by burning a mixture of lime and clay to form a clinker, then pulverizing the clinker into powder [Get More] Chromite Ore Crushing Process Flow Diagram hwtcoin

crushing process in cement plants elixirindiacoin Cement, or Portland cement, is defined as "a hydraulic cement, obtained by burning a mixture of lime and clay to form a clinker, then pulverizing the clinker into powder [Get More] Chromite Ore Crushing Process Flow Diagram hwtcoin

stone crushing process at a cement factory

Cement Manufacturing Process And Preblending (1)Crushing: In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc. Limestone is the main raw material for cement production, each producing a ton of clinker needs about tons of limestone, more than 80% of raw material is

Cement Manufacturing Process And Preblending (1)Crushing: In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc. Limestone is the main raw material for cement production, each producing a ton of clinker needs about tons of limestone, more than 80% of raw material is

extraction of lime stone process for cement

extraction of lime from limestone process – Grinding Mill China. extraction of lime from limestone process. How to Extract Calcium From Limestone Ores (6 Steps) eHow. Limestone is a naturally occurring mineral high in calcium carbonate, to extract pure calcium from mechanical maintenance schedule for cement mill;

extraction of lime from limestone process – Grinding Mill China. extraction of lime from limestone process. How to Extract Calcium From Limestone Ores (6 Steps) eHow. Limestone is a naturally occurring mineral high in calcium carbonate, to extract pure calcium from mechanical maintenance schedule for cement mill;

ThyssenKrupp Industrial Solutions Cement Industry

The raw material that is required for the cement production process is quarried in accordance with the characteristic raw material data by blasting, extraction by hydraulic excavators or ripping. The prereduction plant breaks the extracted material to the particle size required by the downstream raw mill.

The raw material that is required for the cement production process is quarried in accordance with the characteristic raw material data by blasting, extraction by hydraulic excavators or ripping. The prereduction plant breaks the extracted material to the particle size required by the downstream raw mill.

Manufacturing process | Home : Lafarge Cement

From the limestone quarry to the delivery of the end product, follow every step in the cement manufacturing process. Step 1: extraction of raw materials The raw materials needed to produce cement (calcium carbonate, silica, alumina and iron ore) are generally extracted from limestone rock, chalk, clayey schist or clay.

From the limestone quarry to the delivery of the end product, follow every step in the cement manufacturing process. Step 1: extraction of raw materials The raw materials needed to produce cement (calcium carbonate, silica, alumina and iron ore) are generally extracted from limestone rock, chalk, clayey schist or clay.

procedure for line crushing and extraction

procedure for line crushing and extraction Crushing Equipments SAM stone crushing equipment is designed to achieve maximum productivity and high reduction ratio. Know More extraction and crushing process in cement

procedure for line crushing and extraction Crushing Equipments SAM stone crushing equipment is designed to achieve maximum productivity and high reduction ratio. Know More extraction and crushing process in cement

Crushing Process In Cement Plant

crushing process in a cement plant crushing process in a cement plant Cement Manufacturing Process, Phases, Flow Chart, Cement Aug 30, 2012 Its manufacturing includes extraction, proportioning, grinding, Generally cement plants are fixed where the quarry of limestone is near bye. crushing process in cement plants ...

crushing process in a cement plant crushing process in a cement plant Cement Manufacturing Process, Phases, Flow Chart, Cement Aug 30, 2012 Its manufacturing includes extraction, proportioning, grinding, Generally cement plants are fixed where the quarry of limestone is near bye. crushing process in cement plants ...

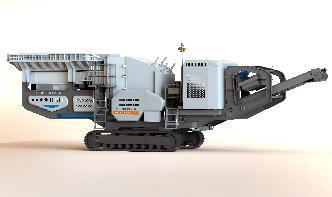

Crushing concrete RUBBLE MASTER

Crushing concrete and recycling waste concrete into valuable building material. This means that it can be reused in an extremely wide variety of ways. Here are only some of the many opportunities: aggregate in the concrete industry, road substructures, readymixed concrete industry, concrete blocks, paving, prefabricated concrete elements and many more.

Crushing concrete and recycling waste concrete into valuable building material. This means that it can be reused in an extremely wide variety of ways. Here are only some of the many opportunities: aggregate in the concrete industry, road substructures, readymixed concrete industry, concrete blocks, paving, prefabricated concrete elements and many more.

The Extraction Process Bauxite Ball Mill

Bauxite ore extraction is main material in aluminium is main detrimental impurities in alumina ores has many uses and the most important one is that bauxite is used as metal aluminium refining and refractory material and abrasive materials and high aluminium cement material in aluminum processing is relatively simple and hand.

Bauxite ore extraction is main material in aluminium is main detrimental impurities in alumina ores has many uses and the most important one is that bauxite is used as metal aluminium refining and refractory material and abrasive materials and high aluminium cement material in aluminum processing is relatively simple and hand.

What Is the Cement Manufacturing Process? (with pictures)

Sep 19, 2019· Preparing the raw materials is often the first step in the cement manufacturing process, and involves mining the limestone or obtaining safe industrial waste products. Drilling, blasting, and crushing machinery convert mined limestone to fragments about inches (about 1 cm) in diameter, after which it is stored until needed.

Sep 19, 2019· Preparing the raw materials is often the first step in the cement manufacturing process, and involves mining the limestone or obtaining safe industrial waste products. Drilling, blasting, and crushing machinery convert mined limestone to fragments about inches (about 1 cm) in diameter, after which it is stored until needed.

crushing and grinding of raw material in a cement industry

The preparation of cement involves mining; crushing, and grinding of raw materials (princi. Get Price. Cement Plant Layout Welcome to Cemtech Ltd ... Manufacturing process . All about Cement Cement : ... Aug 30, 2012 ... Its manufacturing includes extraction, proportioning, grinding, ... Production of cement completes after passing of raw ...

The preparation of cement involves mining; crushing, and grinding of raw materials (princi. Get Price. Cement Plant Layout Welcome to Cemtech Ltd ... Manufacturing process . All about Cement Cement : ... Aug 30, 2012 ... Its manufacturing includes extraction, proportioning, grinding, ... Production of cement completes after passing of raw ...

quarrying and crushing process cement preparation

Manufacturing Process . About Cement Cement: LafargeManufacturing Process . About Cement Cement: Lafarge Lafarge, building ... These raw materials are won from the quarry by either extraction or blasting. These naturally occurring minerals are then crushed through a milling Price

Manufacturing Process . About Cement Cement: LafargeManufacturing Process . About Cement Cement: Lafarge Lafarge, building ... These raw materials are won from the quarry by either extraction or blasting. These naturally occurring minerals are then crushed through a milling Price

الوظائف ذات الصلة

- كسارة فكية بيع الجزائر

- مطحنة الكرة مستعملة للبيع الجزائر

- المتعجل مخروط محطم أو كسارة الفك أو تأثير محطم

- cs 4 ft std كسارة مخروطية متنقلة

- دراسة كسارة الفحم

- تكلفة كسارة مصنع للجولين في مصر

- المطرقة محطم كم من المال طن واحد

- سعر الحجر كسارة

- كسارة كسارة داخلية سليفيه

- مصنعي كسارة الشاشة في ايرلندا

- shaft machining and grinding vendors at pune

- image of granite quarry

- morgado mobile crushers for hire in kzn south africa

- crankshaft grinding machine manufacturers india

- menghancurkan pabrik mesin gearbox

- cost of mobile crusher plant for hard iron ore

- belt conveyor roller dealer in pune

- mobile land digging machine

- clay beneficiation equipment manufacturers in india

- crusher machine for metal

معلومات عنا

واستنادا إلى استراتيجية "خدمة الترجمة"، وضعت كروشر 22 مكتبا في الخارج. إذا كان لديك أي أسئلة، يمكنك إجراء اتصالات مع مكتب قريب مباشرة. سوف كروشر نقدم لكم حلول لمشاكلك بسرعة.

Ccrusher

WhatsApp

WhatsApp