vertical raw mill animation in iran

Cement Production: How Cement Is Manufactured | CEMEX UK

6. Raw material mill. This takes places in vertical steel mill, which grinds the material through the pressure exerted by three conical rollers. Which roll over a turning milling table. Horizontal mills, inside which the material is pulverized by means of steel balls, are also used in this phase.

6. Raw material mill. This takes places in vertical steel mill, which grinds the material through the pressure exerted by three conical rollers. Which roll over a turning milling table. Horizontal mills, inside which the material is pulverized by means of steel balls, are also used in this phase.

Rolling (metalworking) Wikipedia

Hot rolling is a metalworking process that occurs above the recrystallization temperature of the material. After the grains deform during processing, they recrystallize, which maintains an equiaxed microstructure and prevents the metal from work hardening. The starting material is usually large pieces of metal, like semifinished casting products, such as slabs, blooms, and billets.

Hot rolling is a metalworking process that occurs above the recrystallization temperature of the material. After the grains deform during processing, they recrystallize, which maintains an equiaxed microstructure and prevents the metal from work hardening. The starting material is usually large pieces of metal, like semifinished casting products, such as slabs, blooms, and billets.

Japan | INTERNATIONAL SERICULTURAL COMMISSION

In 1901, Japan's production of raw silk surpassed that of France and Italy, and in 1907, Japan's export of raw silk exceeded that of China, making Japan the top exporter of raw silk in the world. From 1941, due to the impacts of the World War II, production and export of raw silk in Japan began to decline.

In 1901, Japan's production of raw silk surpassed that of France and Italy, and in 1907, Japan's export of raw silk exceeded that of China, making Japan the top exporter of raw silk in the world. From 1941, due to the impacts of the World War II, production and export of raw silk in Japan began to decline.

Estimating Steel Players MTU

Raw steel used to fabricate structural steel members can be purchased from a steel mill or steel service center. Material purchased from a steel service center is usually more expensive, but may be quicker to obtain and can be ordered in smaller quantities. The material for the case study project was

Raw steel used to fabricate structural steel members can be purchased from a steel mill or steel service center. Material purchased from a steel service center is usually more expensive, but may be quicker to obtain and can be ordered in smaller quantities. The material for the case study project was

VisualMill CADCAM Software for Sale | CNC Masters

The VisualMill CADCAM software from CNC Masters is an integral part of CNC Jr. Supra Milling Machines. Click here for more info contact us today!

The VisualMill CADCAM software from CNC Masters is an integral part of CNC Jr. Supra Milling Machines. Click here for more info contact us today!

Metal Forming Process:Rolling, Forging, Extrusion ...

High Rolling mill: It consists of two rolling mills which are rotated in opposite directions to each other. The material is to be passed in between these two rolling mills such that the compressive forces can changes its thickness from the original.

High Rolling mill: It consists of two rolling mills which are rotated in opposite directions to each other. The material is to be passed in between these two rolling mills such that the compressive forces can changes its thickness from the original.

The Mill

The Mill's legacy is rooted in making the impossible, possible, helping to bring to life the most imaginative and creative briefs. At the core of this legacy is our animal and creature work. By combining the very latest technology with.

The Mill's legacy is rooted in making the impossible, possible, helping to bring to life the most imaginative and creative briefs. At the core of this legacy is our animal and creature work. By combining the very latest technology with.

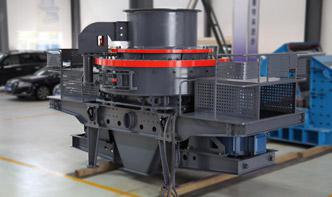

Vertical Roller Mill Repair | Castolin Eutectic

In the 70s, vertical roller mills became increasingly dominant for grinding raw materials mainly for the cement industry due to their high energy efficiency and excellent drying capacity. For many years, Castolin Eutectic´s expert knowhow, together with our stateoftheart technologies, have been used to repair VRMs throughout the world, increasing dramatically their lifetimes.

In the 70s, vertical roller mills became increasingly dominant for grinding raw materials mainly for the cement industry due to their high energy efficiency and excellent drying capacity. For many years, Castolin Eutectic´s expert knowhow, together with our stateoftheart technologies, have been used to repair VRMs throughout the world, increasing dramatically their lifetimes.

Party sing along with Mitch Internet Archive

Popular songs; vocal chorus with instrumental ensemble ; MitchMiller, musical director Lyrics printed on container; 4 additional, detachable lyric sheets bound to container I love you truly In the shade of the old apple tree In the good old summertime The sweetest story ever told Meet me tonight in dreamland I wonder who's kissing her now Goodnight, ladies Home, sweet home ...

Popular songs; vocal chorus with instrumental ensemble ; MitchMiller, musical director Lyrics printed on container; 4 additional, detachable lyric sheets bound to container I love you truly In the shade of the old apple tree In the good old summertime The sweetest story ever told Meet me tonight in dreamland I wonder who's kissing her now Goodnight, ladies Home, sweet home ...

The cement mill

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum .

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum .

CNC Milling: Introduction to cutting tools | wikimal

In end milling, the cutter generally rotates on an axis vertical to the workpiece. Cutting teeth are located on both the end face of the cutter and the periphery of the cutter body. A ball nose end mill, also known as a spherical end mill or ball end mill, has a semisphere at the tool end.

In end milling, the cutter generally rotates on an axis vertical to the workpiece. Cutting teeth are located on both the end face of the cutter and the periphery of the cutter body. A ball nose end mill, also known as a spherical end mill or ball end mill, has a semisphere at the tool end.

GGBS Vertical Roller Mill

Slag powder vertical roller mill adopts the internal negative pressure system to reduce the dust spillover effectively. The equipment adopts advanced technology with low revolving speed, stable operation, low noise, and the noise does not exceed 85dB(A) from the mill 1 meter. 4. Removing iron effectively, increasing additional income.

Slag powder vertical roller mill adopts the internal negative pressure system to reduce the dust spillover effectively. The equipment adopts advanced technology with low revolving speed, stable operation, low noise, and the noise does not exceed 85dB(A) from the mill 1 meter. 4. Removing iron effectively, increasing additional income.

Effect of raw material properties and die geometry on the ...

Effect of raw material properties and die geometry on the density of biomass pellets from composted municipal solid waste Zafari, A., and Kianmehr, M. H. (2012). "Effect of raw material properties and die geometry on the density of biomass pellets from composted municipal solid .

Effect of raw material properties and die geometry on the density of biomass pellets from composted municipal solid waste Zafari, A., and Kianmehr, M. H. (2012). "Effect of raw material properties and die geometry on the density of biomass pellets from composted municipal solid .

Calcining cement plant,ball mill,vertical mill,rotary ...

Calcining CHAENG(Great Wall) can produce rotary kiln with diameter Φ1Φ5m, which is widely used in metallurgy, steel, chemical, refractory, ceramsite, papermaking industries. The kiln supporting has rolling and sliding type and the drive can use DC or AC variable frequency control.

Calcining CHAENG(Great Wall) can produce rotary kiln with diameter Φ1Φ5m, which is widely used in metallurgy, steel, chemical, refractory, ceramsite, papermaking industries. The kiln supporting has rolling and sliding type and the drive can use DC or AC variable frequency control.

Cemtech MEA 2019

The facility was constructed by Sinoma in 2012 and features a fivestage, twinstring preheater and 10,000tpd kiln. Two Loesche vertical raw mills grind raw material at a capacity of 400tph, while cement grinding is carried out by three additional +3C/S mills at a capacity of 210tph.

The facility was constructed by Sinoma in 2012 and features a fivestage, twinstring preheater and 10,000tpd kiln. Two Loesche vertical raw mills grind raw material at a capacity of 400tph, while cement grinding is carried out by three additional +3C/S mills at a capacity of 210tph.

Pulverizer Wikipedia

Similar to the ring and ball mill, the vertical spindle roller mill uses large "tires" to crush the coal. These mills are usually found in utility plants. Raw coal is gravityfed through a central feed pipe to the grinding table where it flows outwardly by centrifugal action and is ground between the rollers and table.

Similar to the ring and ball mill, the vertical spindle roller mill uses large "tires" to crush the coal. These mills are usually found in utility plants. Raw coal is gravityfed through a central feed pipe to the grinding table where it flows outwardly by centrifugal action and is ground between the rollers and table.

Vertical roller mill services

The vertical roller mill (VRM) is firmly established in cement plants all over the world. The biggest issues facing plants are not due to the equipment itself, but more to do with how well mill maintenance is understood and how the mill is looked after following commissioning.

The vertical roller mill (VRM) is firmly established in cement plants all over the world. The biggest issues facing plants are not due to the equipment itself, but more to do with how well mill maintenance is understood and how the mill is looked after following commissioning.

Vertical Mill VM936E | Baileigh Industrial

Baileigh Industrial's VM936E milling machine is a great vertical mill for those small fabrication shops or educational institutions looking for a good quality vertical mill for a great price. The VM936E comes with a lot of standard features making it fit right in the Baileigh Industrial line up.

Baileigh Industrial's VM936E milling machine is a great vertical mill for those small fabrication shops or educational institutions looking for a good quality vertical mill for a great price. The VM936E comes with a lot of standard features making it fit right in the Baileigh Industrial line up.

Essa® ABM200 Auto Batch Mill FL

The Essa® ABM200 Auto Batch Mill is a versatile laboratory pulverising mill that can be installed as a standalone, manually operated machine, or as part of a robotic cell. Its design is based on the highly successful combination of an Essa Model LM2 batch pulverising mill .

The Essa® ABM200 Auto Batch Mill is a versatile laboratory pulverising mill that can be installed as a standalone, manually operated machine, or as part of a robotic cell. Its design is based on the highly successful combination of an Essa Model LM2 batch pulverising mill .

Making gains with the OK™ Mill

Among these is Shah Cement, which has ordered the world's largest OK Mill. The OK™ 816 Mill features six rollers and an diameter grinding table, boasting an installed power of 11,600 KW. The trend towards larger OK™ Mills in Bangladesh is helping cement producers keep up with the boom in infrastructure development.

Among these is Shah Cement, which has ordered the world's largest OK Mill. The OK™ 816 Mill features six rollers and an diameter grinding table, boasting an installed power of 11,600 KW. The trend towards larger OK™ Mills in Bangladesh is helping cement producers keep up with the boom in infrastructure development.

PEERREVIEWED ARTICLE bioresources

under axial stress from a vertical piston applied by a hydraulic press. The effects of independent variables, including the raw material moisture content (35 to 45% (wet basis)), hammer mill screen size ( to mm), speed of piston (2 to 10 mm/s), and die length (8 to 12 mm) on

under axial stress from a vertical piston applied by a hydraulic press. The effects of independent variables, including the raw material moisture content (35 to 45% (wet basis)), hammer mill screen size ( to mm), speed of piston (2 to 10 mm/s), and die length (8 to 12 mm) on

Cement Production: How Cement Is Manufactured | CEMEX UK

Raw material mill. This takes places in vertical steel mill, which grinds the material through the pressure exerted by three conical rollers. Which roll over a turning milling table. Horizontal mills, inside which the material is pulverized by means of steel balls, are also used in this phase.

Raw material mill. This takes places in vertical steel mill, which grinds the material through the pressure exerted by three conical rollers. Which roll over a turning milling table. Horizontal mills, inside which the material is pulverized by means of steel balls, are also used in this phase.

الوظائف ذات الصلة

- المعايير الصناعية لسحق الحجر الجيري

- 200-400 الهيدروكربونات النفطية محطة كسارة الحجر

- مصنع كسارة مخروطية عمان

- كسارة الجرانيت المتنقلة في دي مندوب الكونغو

- الحجر كسارة بسعة 100 الهيدروكربونات النفطية

- كسارة الفحم للفحم كبيرة الحجم

- أين يمكنني شراء الكسارة الأساسية في مصر

- حجر المحاجر سعر الجهاز في مصر

- حل لنسبة الإسمنت والحصى m20

- maquina para moler ladrillos marca mazza

- high quality crushing machine for sale in iran with ce iso

- copper sulfate stainless steel

- impact crusher performance parameters

- compaction of 2 inch crusher run gravel

- digunakan penghancur batu eropa

- portable diamond mobile

- or consseur and justin bieber

- simons cone crushers in china

- exhibition in china

- crusher in maracaibo sale

معلومات عنا

واستنادا إلى استراتيجية "خدمة الترجمة"، وضعت كروشر 22 مكتبا في الخارج. إذا كان لديك أي أسئلة، يمكنك إجراء اتصالات مع مكتب قريب مباشرة. سوف كروشر نقدم لكم حلول لمشاكلك بسرعة.

Ccrusher

WhatsApp

WhatsApp