calcination or roasting of ore html

Drying, Roasting, and Calcining of Minerals | Wiley Online ...

The papers in this volume give the reader focused information on the important extractive metallurgy unit operations of drying, roasting, and calcining Table of Contents GO TO PART

The papers in this volume give the reader focused information on the important extractive metallurgy unit operations of drying, roasting, and calcining Table of Contents GO TO PART

China Supplier Iron Ore Calcination Sponge Iron Rotary ...

Metallurgy chemical kiln is widely used for magnetic roasting of poor iron ore and oxidizing roasting of chrome and nickel in the steel factory; backing highalumina mine in the refractory material factory; baking chamotte and alumina in the aluminum factory and .

Metallurgy chemical kiln is widely used for magnetic roasting of poor iron ore and oxidizing roasting of chrome and nickel in the steel factory; backing highalumina mine in the refractory material factory; baking chamotte and alumina in the aluminum factory and .

roasting copper ore

chapter viii calcination or roasting of ores. The object of calcining or roasting certain ores before treatment is to dissipate the sulphur or sulphides of . Smelting Wikipedia, the free encyclopedia

chapter viii calcination or roasting of ores. The object of calcining or roasting certain ores before treatment is to dissipate the sulphur or sulphides of . Smelting Wikipedia, the free encyclopedia

pilot ore roasting kiln for sale

Iron Ore Roasting Rotary Kiln for Sale Iron Ore Roasting Rotary Kiln for Sale Savona Equipment is your supplier for new, used, and rebuilt ore roasting rotary kiln. There are two basic types of rotary kilns; direct fired and indirect fired. Rotary Kilns are a pyroprocessing device used to raise materials to a high temperature (calcination) in a ...

Iron Ore Roasting Rotary Kiln for Sale Iron Ore Roasting Rotary Kiln for Sale Savona Equipment is your supplier for new, used, and rebuilt ore roasting rotary kiln. There are two basic types of rotary kilns; direct fired and indirect fired. Rotary Kilns are a pyroprocessing device used to raise materials to a high temperature (calcination) in a ...

smelting and roasting gold and silver ore

Smelting and Roasting Ores to recover gold, silver and, Heating ores to elevated temperatures is called roasting, and it causes the oxygen in the air to convert the sulfur in the ore to sulfur dioxide, which is a gas and is emitted to the air The process works best when the ore is crushed to small pieces before roasting.

Smelting and Roasting Ores to recover gold, silver and, Heating ores to elevated temperatures is called roasting, and it causes the oxygen in the air to convert the sulfur in the ore to sulfur dioxide, which is a gas and is emitted to the air The process works best when the ore is crushed to small pieces before roasting.

calcination or roasting of ore

CALCINATION OR ROASTING OF ORES The object of calcining or roasting certain ores before treatment is to dissipate the sulphur or sulphides of arsenic, . Calcination eNotes. In both calcination and roasting, an ore is converted into its oxide, albeit through different chemical pathway Calcination is the process in which the ore is heated below ...

CALCINATION OR ROASTING OF ORES The object of calcining or roasting certain ores before treatment is to dissipate the sulphur or sulphides of arsenic, . Calcination eNotes. In both calcination and roasting, an ore is converted into its oxide, albeit through different chemical pathway Calcination is the process in which the ore is heated below ...

Rotary Kiln Roasting Of Copper Ores

Iron Ore Roasting Rotary Kiln for Sale Savona Equipment. Rotary Kilns Rotary Kilns are a pyroprocessing device used to raise materials to a high temperature (calcination) in a continuous process Materials produced using rotary kilns include: They are also used for roasting a wide variety of sulfide ores prior to metal extraction The kiln is a ...

Iron Ore Roasting Rotary Kiln for Sale Savona Equipment. Rotary Kilns Rotary Kilns are a pyroprocessing device used to raise materials to a high temperature (calcination) in a continuous process Materials produced using rotary kilns include: They are also used for roasting a wide variety of sulfide ores prior to metal extraction The kiln is a ...

Difference Between Roasting and Calcination – Difference Wiki

Jul 05, 2016· If the ore is not an oxide ore then first it is converted to an oxide ore by the process of calcination or roasting. In calcination, the ore is heated below its melting point either in the absence of the air or less amount of air supply while in roasting, the ore is heated strongly in the presence of air below its melting point.

Jul 05, 2016· If the ore is not an oxide ore then first it is converted to an oxide ore by the process of calcination or roasting. In calcination, the ore is heated below its melting point either in the absence of the air or less amount of air supply while in roasting, the ore is heated strongly in the presence of air below its melting point.

roasting of ores

Calcination or Roasting of Ores CALCINATION OR ROASTING OF ORES. The object of calcining or roasting certain ores before treatment is to dissipate the sulphur or sulphides of arsenic, antimony, lead, etc., which are inimical to treatment, whether by ordinary mercuric amalgamation or lixiviation.

Calcination or Roasting of Ores CALCINATION OR ROASTING OF ORES. The object of calcining or roasting certain ores before treatment is to dissipate the sulphur or sulphides of arsenic, antimony, lead, etc., which are inimical to treatment, whether by ordinary mercuric amalgamation or lixiviation.

calcination definition, etymology and usage, examples ...

n calcination The process of being calcined, or heated with access of air: nearly equivalent to roasting. n calcination The process of treating certain ores, especially of iron, for the purpose of making them more manageable in the furnace, nothing being taken from or added to the material thus treated. This is done with some Swedish iron ores.

n calcination The process of being calcined, or heated with access of air: nearly equivalent to roasting. n calcination The process of treating certain ores, especially of iron, for the purpose of making them more manageable in the furnace, nothing being taken from or added to the material thus treated. This is done with some Swedish iron ores.

1. CHEMICAL .

Roasting Roasting is one of the oxidation method where ore is converted into metal oxide. In the process of roasting, the ore either alone or with the addition of suitable material, is subjected to the action of heat in excess of air at temperature below its melting point. 2ZnS + 3O2>2ZnO + 2SO 2 Calcination

Roasting Roasting is one of the oxidation method where ore is converted into metal oxide. In the process of roasting, the ore either alone or with the addition of suitable material, is subjected to the action of heat in excess of air at temperature below its melting point. 2ZnS + 3O2>2ZnO + 2SO 2 Calcination

Conversion of Ore Into Metallic Oxide: Calcination and ...

This on calcination gives zinc oxide. Sodium bicarbonate on calcination gives sodium carbonate FeCO. HeatFe0+ CO, ZnC03Heat ZnO + CO, e) Heat. Roasting the presence of air This method is employed Calcination Ore is heated stongly Ore is heated strongly in in the absence or lirnited supply of air. This method is employed for carbonate for sulphide ores. ores CO2 gas is produced.

This on calcination gives zinc oxide. Sodium bicarbonate on calcination gives sodium carbonate FeCO. HeatFe0+ CO, ZnC03Heat ZnO + CO, e) Heat. Roasting the presence of air This method is employed Calcination Ore is heated stongly Ore is heated strongly in in the absence or lirnited supply of air. This method is employed for carbonate for sulphide ores. ores CO2 gas is produced.

chemistry stuff : Extraction of Iron (Fe) from its haematite

Sep 13, 2013· Calcination or Roasting of ore. The concentrated ore is now heated in the presence of air. The process of roasting is performed to remove moisture, CO 2, impurities of sulphur, arsenic. Ferrous oxide is also oxidized to ferric oxide. ... Extraction of Iron (Fe) from its haematite; About Me. crazyb View my complete profile.

Sep 13, 2013· Calcination or Roasting of ore. The concentrated ore is now heated in the presence of air. The process of roasting is performed to remove moisture, CO 2, impurities of sulphur, arsenic. Ferrous oxide is also oxidized to ferric oxide. ... Extraction of Iron (Fe) from its haematite; About Me. crazyb View my complete profile.

Minerals Ores Extraction of Metals Metallurgy SKM ...

The extraction of metals from their ores and then refining them for use is known as metallurgy Steps involved in Extraction of metals from ore include dressing or ore, concentration, roasting and calcination .

The extraction of metals from their ores and then refining them for use is known as metallurgy Steps involved in Extraction of metals from ore include dressing or ore, concentration, roasting and calcination .

Minerals Ores Extraction of Metals Metallurgy SKM ...

The sulphide ores are converted into oxides by heating strongly in the presence of excess air. This process is known as roasting. The carbonate ores are changed into oxides by heating strongly in limited air. This process is known as calcination. 1. Roasting:2Zns(s) + 3O2 (g) heat > 2ZnO +2SO2 (g)

The sulphide ores are converted into oxides by heating strongly in the presence of excess air. This process is known as roasting. The carbonate ores are changed into oxides by heating strongly in limited air. This process is known as calcination. 1. Roasting:2Zns(s) + 3O2 (g) heat > 2ZnO +2SO2 (g)

Minerals | Free FullText | Transformation of Vanadium ...

The roasting of the ore is necessary for improving the leaching efficiency and roasting at 1200 °C for 2 h under the air atmosphere is appropriate to minimize vanadium loss and reduce energy consumption by % compared with roasting at 1250 °C for 2 h (based on laboratory conditions).

The roasting of the ore is necessary for improving the leaching efficiency and roasting at 1200 °C for 2 h under the air atmosphere is appropriate to minimize vanadium loss and reduce energy consumption by % compared with roasting at 1250 °C for 2 h (based on laboratory conditions).

Conversion of Ore into Metal Oxide

Example of how calamine ore or zinc carbonate is converted to ZnO by calcination is shown below. Calcination can be done for ores containing carbonates. Roasting is a process of oxidizing zinc sulfide concentrates at high temperatures into an impure zinc oxide, called "Zinc Calcine".

Example of how calamine ore or zinc carbonate is converted to ZnO by calcination is shown below. Calcination can be done for ores containing carbonates. Roasting is a process of oxidizing zinc sulfide concentrates at high temperatures into an impure zinc oxide, called "Zinc Calcine".

laterite nickel ore roasting kiln

laterite ores will be critical sustainability issues affecting the future of the nickel laterite industry. One commonly used processing method for nickel extraction via the pyrometallurgical treatment of laterite ores involves smelting to ferronickel in a rotary kiln electric furnace process. The reduction roasting of laterite ore .

laterite ores will be critical sustainability issues affecting the future of the nickel laterite industry. One commonly used processing method for nickel extraction via the pyrometallurgical treatment of laterite ores involves smelting to ferronickel in a rotary kiln electric furnace process. The reduction roasting of laterite ore .

Heating of an ore below its melting point in presence of ...

Heating of an ore below its melting point in presence of excess of air is called a) Calcination b) Smelting c) Roasting d) Sublimation

Heating of an ore below its melting point in presence of excess of air is called a) Calcination b) Smelting c) Roasting d) Sublimation

Roasting Kiln For The Iron Ore,Manganese Ore,Bauxite Ore ...

Roasting Kiln For The Iron Ore,Manganese Ore,Bauxite Ore, Find Complete Details about Roasting Kiln For The Iron Ore,Manganese Ore,Bauxite Ore,High Quality Roasting Kiln,Rotary Roasting Kiln,Baking Kiln from Cement Making Machinery Supplier or ManufacturerHenan Yuhong Heavy Machinery Co., Ltd.

Roasting Kiln For The Iron Ore,Manganese Ore,Bauxite Ore, Find Complete Details about Roasting Kiln For The Iron Ore,Manganese Ore,Bauxite Ore,High Quality Roasting Kiln,Rotary Roasting Kiln,Baking Kiln from Cement Making Machinery Supplier or ManufacturerHenan Yuhong Heavy Machinery Co., Ltd.

Minerals | Free FullText | The Correlation of Roasting ...

In this study, potassium extraction from feldspar ore was studied using chloridizing (CaCl 2) roasting followed by leaching, and the variable parameters such as solvent type and particle size were investigated by extensively adapting the calcination temperature–duration correlation for the first time. In this study, systematic analyses using ...

In this study, potassium extraction from feldspar ore was studied using chloridizing (CaCl 2) roasting followed by leaching, and the variable parameters such as solvent type and particle size were investigated by extensively adapting the calcination temperature–duration correlation for the first time. In this study, systematic analyses using ...

Pretreatment Process on Refractory Gold Ores with As

Segregation roasting is to dead roast gold ore concentrate with As to remove As. High concentration of flue gas generated during the procedure should be recycled to further process. The calcine of output makes separateon with a certain amount of reductant and chlorating agent.

Segregation roasting is to dead roast gold ore concentrate with As to remove As. High concentration of flue gas generated during the procedure should be recycled to further process. The calcine of output makes separateon with a certain amount of reductant and chlorating agent.

الوظائف ذات الصلة

- كسارة المطرقة مورد مصر

- كسارة للإيجار السعودية جزيره العرب

- آلة طحن الأوروبية

- المستخدمة كسارة حجر في السعر عمان

- مُصنع وسائط طحن في مصر

- آلات المحاجر اليدوية الصغيرة الحجم المستخدمة

- المطرقة عكسها آلة محطم

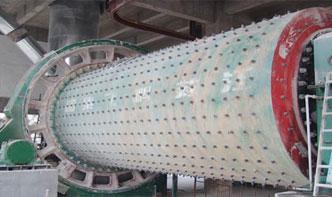

- والتعلم عن مطحنة الكرة

- مشغلي دليل كسارة مخروطية محمولة

- صخرة محطم اهتزازي

- تستخدم كسارة الكلي لل بيع

- helix flexible screw conveyors pdf

- computer aided design of jaw crusher

- produksi penggiling dalam

- how does dakota freds d rocker work

- video of manufacturing process of poly sand tiles

- structural dynamics laboratory manual

- salt mine in dome

- stone crusher sample balance sheet html

- drum roll crusher

معلومات عنا

واستنادا إلى استراتيجية "خدمة الترجمة"، وضعت كروشر 22 مكتبا في الخارج. إذا كان لديك أي أسئلة، يمكنك إجراء اتصالات مع مكتب قريب مباشرة. سوف كروشر نقدم لكم حلول لمشاكلك بسرعة.

Ccrusher

WhatsApp

WhatsApp