sizing of vertical mills for raw mix grinding

How can I mix two different ceramics powders via ball ...

Add ethanol to the powders and use a horizontal rotary ball mill (not planetary ball mill) with small cylindrical grinding media (not spherical grinding media) at 60 rpm for a .

Add ethanol to the powders and use a horizontal rotary ball mill (not planetary ball mill) with small cylindrical grinding media (not spherical grinding media) at 60 rpm for a .

Hydraulic system vertical roller mill operation SlideShare

Mar 25, 2015· Hydraulic system vertical roller mill operation. Vertical hydraulic device in mill to mill the internal parts ofthe repair and replacementare convenient and setting,it can only control the grinding roller aspects of opening and closing, and can not control the small aspects ofthe regulation of grinding rollerand the grinding disc distance size.

Mar 25, 2015· Hydraulic system vertical roller mill operation. Vertical hydraulic device in mill to mill the internal parts ofthe repair and replacementare convenient and setting,it can only control the grinding roller aspects of opening and closing, and can not control the small aspects ofthe regulation of grinding rollerand the grinding disc distance size.

Vrm Presentation | Mill (Grinding) | Cement

ROLLER MILL. Used in cement industry Vertical Mills used for Pregrinding of clinker (lumps to coarse powder) Finish grinding (lumps to powder) of Coal/Petcoke for kiln Raw materials for kiln Cement, OPC or mixed Slag, pure or mixed VRM Functions Vertical Roller Mill (VRM) Details feed gate (air lock) mill casing water injection dam ring louvre ring nozzle of material scraper mill outlet ...

ROLLER MILL. Used in cement industry Vertical Mills used for Pregrinding of clinker (lumps to coarse powder) Finish grinding (lumps to powder) of Coal/Petcoke for kiln Raw materials for kiln Cement, OPC or mixed Slag, pure or mixed VRM Functions Vertical Roller Mill (VRM) Details feed gate (air lock) mill casing water injection dam ring louvre ring nozzle of material scraper mill outlet ...

Volume 3, Issue 5, November 2013 Study of Processing and ...

Volume 3, Issue 5, November 2013 ... A raw mill is the equipment used to grind raw materials into "raw mix" during the manufacture of cement. Dry raw mills are the normal technology installed today, allowing minimization of energy consumption and CO2 emissions. Process of raw mill in grinding of raw .

Volume 3, Issue 5, November 2013 ... A raw mill is the equipment used to grind raw materials into "raw mix" during the manufacture of cement. Dry raw mills are the normal technology installed today, allowing minimization of energy consumption and CO2 emissions. Process of raw mill in grinding of raw .

HLM vertical mill

the largest ring roller mill in China, high efficiency low energy consumption, it is the first choice for ultrafine powder production, grain size range: meshes, the output is 22t/h. 1、within 200 meshes : can be used as feed additives, calcium content is more than %, no harmful ingredient.

the largest ring roller mill in China, high efficiency low energy consumption, it is the first choice for ultrafine powder production, grain size range: meshes, the output is 22t/h. 1、within 200 meshes : can be used as feed additives, calcium content is more than %, no harmful ingredient.

Technical papers Archive CADD Mapei

Activators Antimony Blast furnace slag Blended cements Brown discoloration Calcium sulphate Cement additives Cement color Cement microscopy Chemical analysis Chromates Clinker mineralogy Clinkerization Concrete Controlled release Cost reduction Cr(VI) analysis Diffusion Dosing point Drymix mortars Early strengths Encapsulation Ettringite Fly ash Free lime Grinding aid Gypsum dehydration ...

Activators Antimony Blast furnace slag Blended cements Brown discoloration Calcium sulphate Cement additives Cement color Cement microscopy Chemical analysis Chromates Clinker mineralogy Clinkerization Concrete Controlled release Cost reduction Cr(VI) analysis Diffusion Dosing point Drymix mortars Early strengths Encapsulation Ettringite Fly ash Free lime Grinding aid Gypsum dehydration ...

Mod 10Raw Process Engineering Training ...

Process Engineering Training Program MODULE 10 Raw Milling Section Content 1 Crushing – paper 7 2 Size Reduction some basic problems 3 Mill Design Principles 4 Milling Systems paper 11 5 Wet Milling – paper 12 6 Raw Mill Operations 7 Milling Fundamentals 8 The influence of Holdup, Residence Time and Residence Time Distribution on Cement 9 Design Guideline Vertical Spindle Mills for Raw ...

Process Engineering Training Program MODULE 10 Raw Milling Section Content 1 Crushing – paper 7 2 Size Reduction some basic problems 3 Mill Design Principles 4 Milling Systems paper 11 5 Wet Milling – paper 12 6 Raw Mill Operations 7 Milling Fundamentals 8 The influence of Holdup, Residence Time and Residence Time Distribution on Cement 9 Design Guideline Vertical Spindle Mills for Raw ...

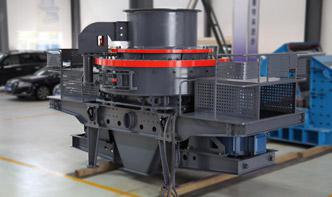

Vertical Roller Mill Manufacturer, Vertical Roller Mill ...

Vertical roller mill spit slag by belt conveyor, bucket elevator to feed mill feed mouth, spit slag belt conveyor is arranged in the electromagnetic iron remover for removing iron. The need of grinding, drying process by setting provides heat source in coal burning hot air furnace before grinding.

Vertical roller mill spit slag by belt conveyor, bucket elevator to feed mill feed mouth, spit slag belt conveyor is arranged in the electromagnetic iron remover for removing iron. The need of grinding, drying process by setting provides heat source in coal burning hot air furnace before grinding.

clinker mill plant design

ball mill for clinker grinding h . Cement Grinding Mill Plant. ball mill for clinker grinding h offers 6710 cement grinding mill plant products. About 65% of these are cast forged, 19% are mine mill, and 5% are cement making machinery. A wide variety of cement grinding mill plant options are available to you, such as free samples, paid samples.

ball mill for clinker grinding h . Cement Grinding Mill Plant. ball mill for clinker grinding h offers 6710 cement grinding mill plant products. About 65% of these are cast forged, 19% are mine mill, and 5% are cement making machinery. A wide variety of cement grinding mill plant options are available to you, such as free samples, paid samples.

air classifier, air separator, cyclone separator

Mill Classification System. Retrofits all types of vertical airswept mills (roller mills, bowl mills, hammer mills, cagemills impactors). Easily replaces existing whizzer or cone separator. Dramatically increases production. Increased top size control. Premium Efficiency Cyclones. Maximum particulate collection.

Mill Classification System. Retrofits all types of vertical airswept mills (roller mills, bowl mills, hammer mills, cagemills impactors). Easily replaces existing whizzer or cone separator. Dramatically increases production. Increased top size control. Premium Efficiency Cyclones. Maximum particulate collection.

clirik vertical roller mill

We are devoted to the ultra fine powder grinding mill. During the past decade, we have accumulated rich experience and have designed and launched the optimized and outstanding vertical roller mills for ultra fine powder. Among which, CLUM series ultrafine powder vertical roller mills are the key products.

We are devoted to the ultra fine powder grinding mill. During the past decade, we have accumulated rich experience and have designed and launched the optimized and outstanding vertical roller mills for ultra fine powder. Among which, CLUM series ultrafine powder vertical roller mills are the key products.

Difference Between Sag Mill vs Ball Mill mech4study

Oct 12, 2017· SAG mill make use of steel balls included with some large and hard rocks for grinding. These mills utilize the balls in making the large fragments of materials broken into pieces. The ball charge of a SAG mill is about 9% to 20%.This process takes place inside the large rotating drum of SAG mill which is filled with balls partially.

Oct 12, 2017· SAG mill make use of steel balls included with some large and hard rocks for grinding. These mills utilize the balls in making the large fragments of materials broken into pieces. The ball charge of a SAG mill is about 9% to 20%.This process takes place inside the large rotating drum of SAG mill which is filled with balls partially.

Optimization of Cement Grinding Operation in Ball Mills ...

Optimization of Cement Grinding Operation in Ball Mills. Contact Us » . Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with ball mills.

Optimization of Cement Grinding Operation in Ball Mills. Contact Us » . Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with ball mills.

CLUM Ultra Fine Vertical Roller Millgrinding mill ...

CLUM Ultra Fine Vertical Roller Mill. Introduction of Ultra fine Vertical Mill CLUM Ultra fine Vertical Mill is a new grinding equipment produced by shanghai Clirik, it can be used in stone powder process with many types. Working principle of Ultra fine Vertical Mill The grinding disc is driving by motor through reducer.

CLUM Ultra Fine Vertical Roller Mill. Introduction of Ultra fine Vertical Mill CLUM Ultra fine Vertical Mill is a new grinding equipment produced by shanghai Clirik, it can be used in stone powder process with many types. Working principle of Ultra fine Vertical Mill The grinding disc is driving by motor through reducer.

HighEfficiency Roller Mills | Industrial Efficiency ...

for raw material grinding, power consumption may range between 14 ~ 17kWh/tmaterial; for coal grinding, power consumption may range between 20 ~ 22kWh/tcoal; slag grinding, electricity consumption may range between 39 ~ 45kWh/tslag. The lifetime of the wear resistant material is reported to vary between 8000 to 12000 hours. (NDRC,2008. ).

for raw material grinding, power consumption may range between 14 ~ 17kWh/tmaterial; for coal grinding, power consumption may range between 20 ~ 22kWh/tcoal; slag grinding, electricity consumption may range between 39 ~ 45kWh/tslag. The lifetime of the wear resistant material is reported to vary between 8000 to 12000 hours. (NDRC,2008. ).

Ball mill Wikipedia

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium.

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium.

Vertical vs. Horizontal Milling CNC Mills, Lathes ...

May 23, 2014· The cutters on a horizontal mill are fashioned something like the blade of a circular saw, but they are generally thicker and smaller. Their size and shape means they can generally cut faster than the spindle of a vertical mill, especially when milling slots and grooves.

May 23, 2014· The cutters on a horizontal mill are fashioned something like the blade of a circular saw, but they are generally thicker and smaller. Their size and shape means they can generally cut faster than the spindle of a vertical mill, especially when milling slots and grooves.

LOESCHE can build on its good standing and deliver more ...

Bim Son – LOESCHE will soon be delivering a vertical roller mill for the grinding of clinker and granulated blast furnace slag for the Vietnamese company Bim Son Cement JSC.

Bim Son – LOESCHE will soon be delivering a vertical roller mill for the grinding of clinker and granulated blast furnace slag for the Vietnamese company Bim Son Cement JSC.

ERSEL Ağır Makine San. ve Tic. A.Ş.

Vertical Roller Mills can make drying, grinding and classifying processes all in one compact machine. Alongside providing large capacities for the grinding of raw materials in soft and medium hardness, Vertical Mills has high energy efficiency compared to the other systems. Easily replaceable wear parts ensures the ease of maintenance.

Vertical Roller Mills can make drying, grinding and classifying processes all in one compact machine. Alongside providing large capacities for the grinding of raw materials in soft and medium hardness, Vertical Mills has high energy efficiency compared to the other systems. Easily replaceable wear parts ensures the ease of maintenance.

GRINDING OPTIMISATION Adapting to the market

up to 20 per cent of energy savings compared with vertical mills. For example, at Republic Cement's Teresa plant in the Philippines, the overall energy consumption for the whole grinding plant is limited to /t (cement type 1P), while at LafargeHolcim's Barroso .

up to 20 per cent of energy savings compared with vertical mills. For example, at Republic Cement's Teresa plant in the Philippines, the overall energy consumption for the whole grinding plant is limited to /t (cement type 1P), while at LafargeHolcim's Barroso .

OPTIMIZING THE CONTROL SYSTEM OF CEMENT MILLING: .

the grinding process remains a challenging issue, due to the elevated degree of uncertainties, process nonlinearity and frequent change of the set points and the respective model parameters during operation. For productivity and quality reasons, grinding is mostly performed in closed circuits: The ball cement mill (CM) is fed with raw materials.

the grinding process remains a challenging issue, due to the elevated degree of uncertainties, process nonlinearity and frequent change of the set points and the respective model parameters during operation. For productivity and quality reasons, grinding is mostly performed in closed circuits: The ball cement mill (CM) is fed with raw materials.

Grinding Mill

The FUTURE of Grinding Industry is HERE! Strong production bases guarantee the normal production of grinding mills and quick is SBM POWER!

The FUTURE of Grinding Industry is HERE! Strong production bases guarantee the normal production of grinding mills and quick is SBM POWER!

RETSCH – Laboratory Mills, Crushers and Sieve Shakers

RETSCH RETSCH – Laboratory Mills, Crushers and Sieve Shakers RETSCH is the leading solution provider for neutraltoanalysis sample preparation and characterization of solids. Based on a century of experience RETSCH develops size reduction and sieving equipment which is characterized by excellent performance, operating convenience, safety and ...

RETSCH RETSCH – Laboratory Mills, Crushers and Sieve Shakers RETSCH is the leading solution provider for neutraltoanalysis sample preparation and characterization of solids. Based on a century of experience RETSCH develops size reduction and sieving equipment which is characterized by excellent performance, operating convenience, safety and ...

الوظائف ذات الصلة

- آلة كسارة خام الذهب في المملكة العربية السعودية

- مستعملة آلات المحجر كاملة للبيع

- صنع الرمل آلة الشعبي

- الشركات المصنعة للمعدات تعدين الذهب في الدنمارك

- سحق في الصناعات الكيماوية مصر

- لانتاج الاسمنت أدوات مصنع

- كسارة خام الذهب الصغيرة للبيع السودان

- المصنعة كسارة حجر في

- كسارات محامل المتداول

- تستخدم معدات كسارة الصخور الصغيرة

- crusher emas peralatan harga new zealand

- bear run mine carlisle indiana commercial

- jaw crusher indian

- best technology for gold mining processing

- mobile placer mining plant

- forage cutter and grinder mill italy

- sample of project proposal on small scale mining

- crushing plant mnfrs worksop

- coal washing process machine price

- pvc cracher wastein uae

معلومات عنا

واستنادا إلى استراتيجية "خدمة الترجمة"، وضعت كروشر 22 مكتبا في الخارج. إذا كان لديك أي أسئلة، يمكنك إجراء اتصالات مع مكتب قريب مباشرة. سوف كروشر نقدم لكم حلول لمشاكلك بسرعة.

Ccrusher

WhatsApp

WhatsApp